Scroll through for details on the design!

Finished ALLS Prototype (on Mock Residual Limb):

Battery/Microcontroller Case SolidWorks Model:

Assembled Socket, Adjustment, and Foam:

Note: foam lining for comfort, removable via velcro for easy cleaning

Note: foam lining for comfort, removable via velcro for easy cleaning

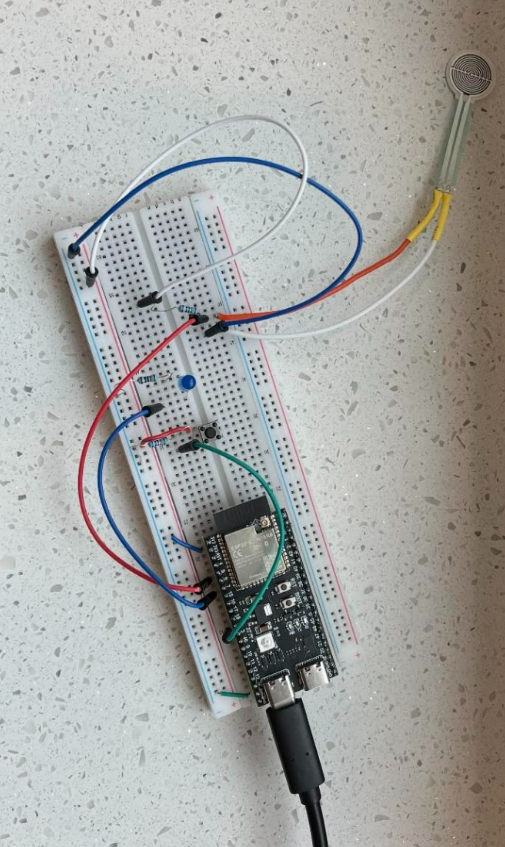

Pressure Sensor Design:

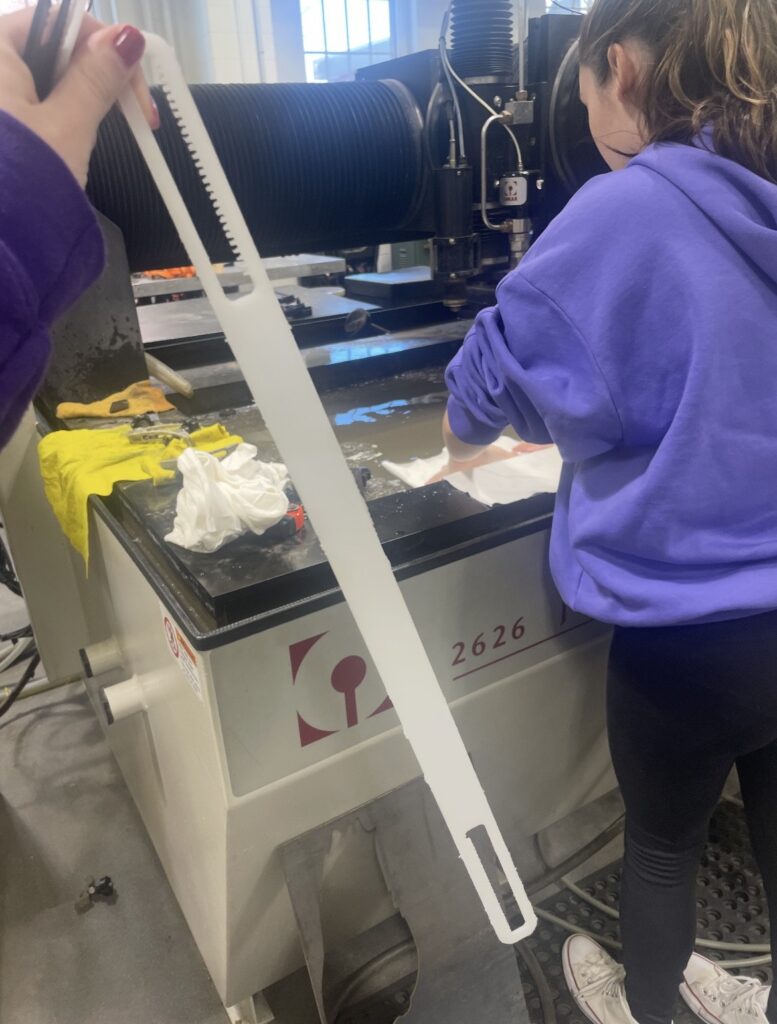

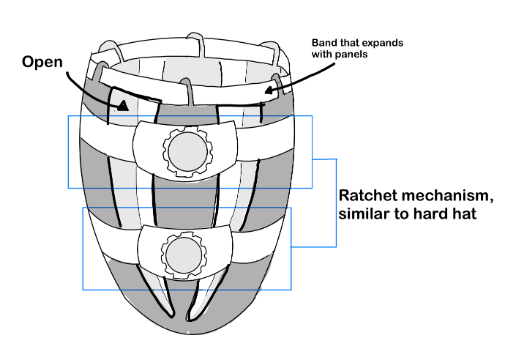

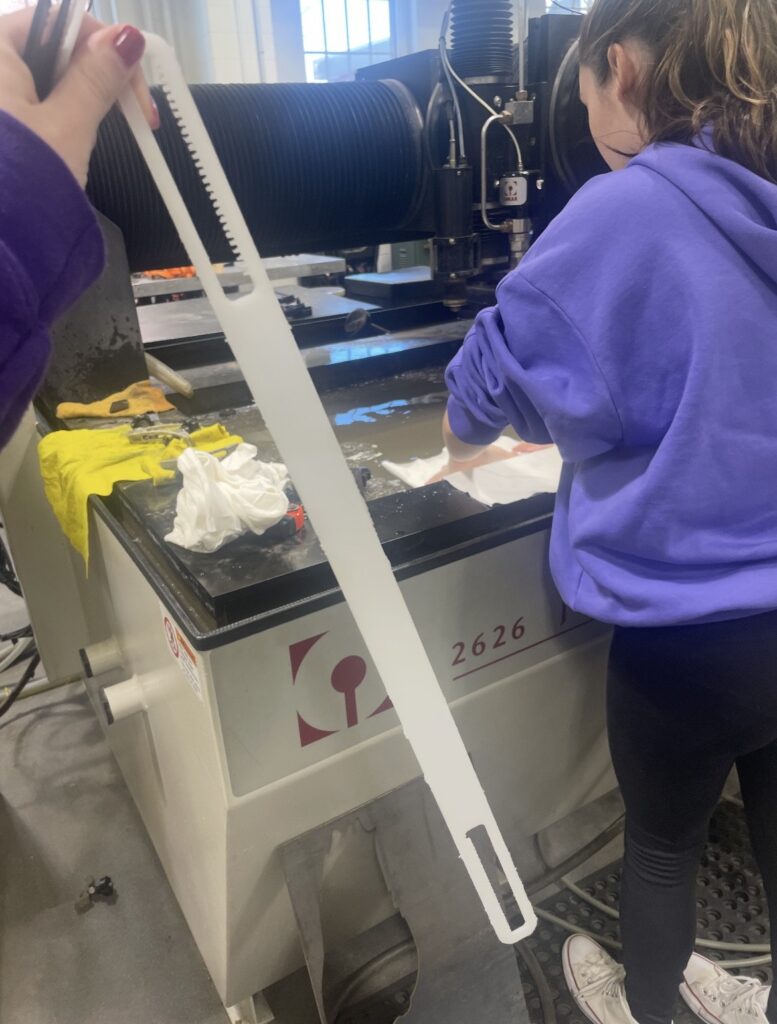

Manufacturing Adjustment Bands:

Bands made from a sheet of High Density Polyethylene (HDPE) by waterjet and milling machine.

Bands made from a sheet of High Density Polyethylene (HDPE) by waterjet and milling machine.

Practicing Drilling Holes in Onyx Sample:

Top hole was done by melting; bottom hole done by drilling. The piece was clamped to the adapter to ensure the holes align correctly!

Top hole was done by melting; bottom hole done by drilling. The piece was clamped to the adapter to ensure the holes align correctly!

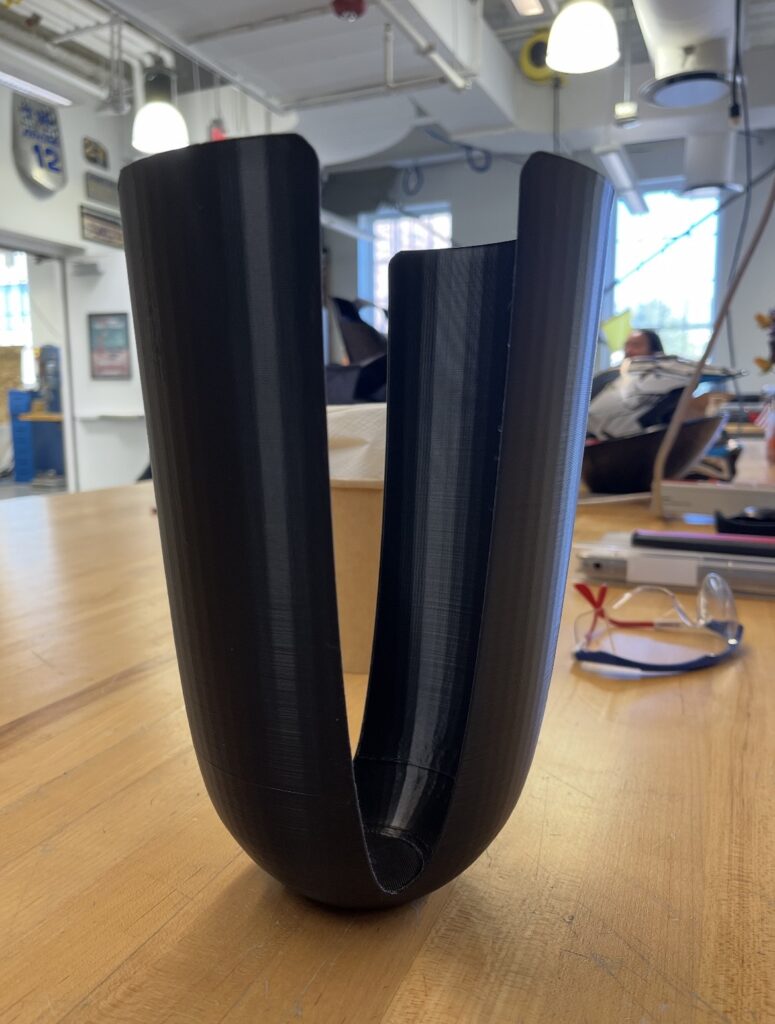

Test Printing Entire Socket Geometry:

Test Printing of Bottom of the Socket (PLA):

Test print to ensure the bottom of the socket fits in the adapter correctly!

Test print to ensure the bottom of the socket fits in the adapter correctly!

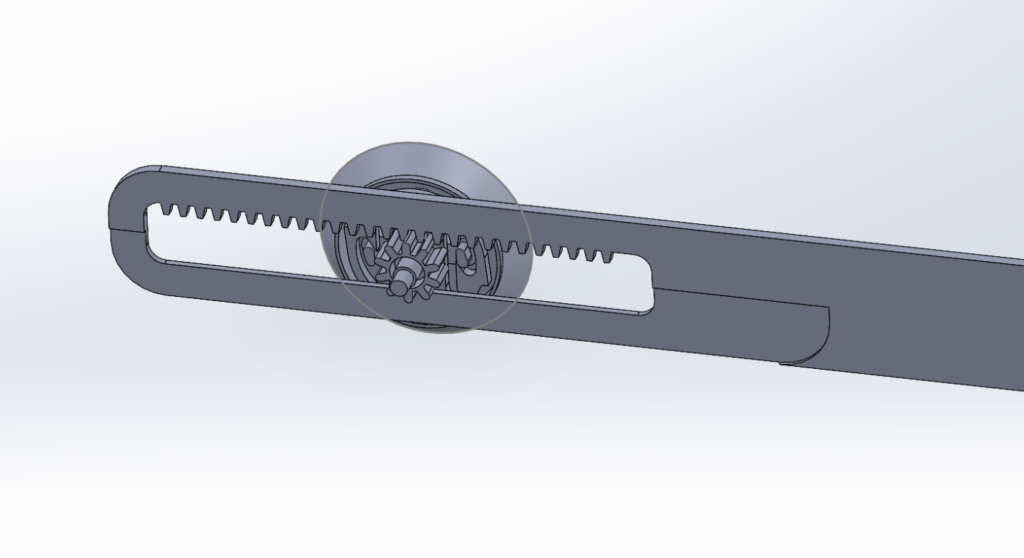

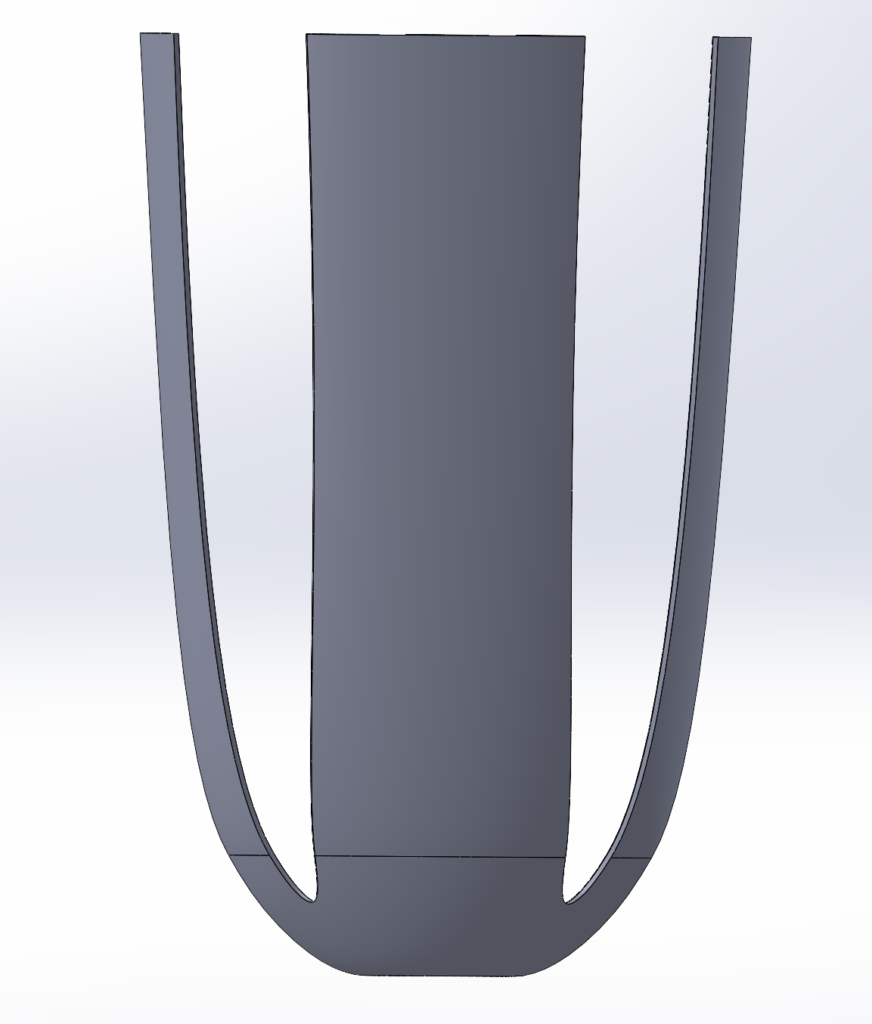

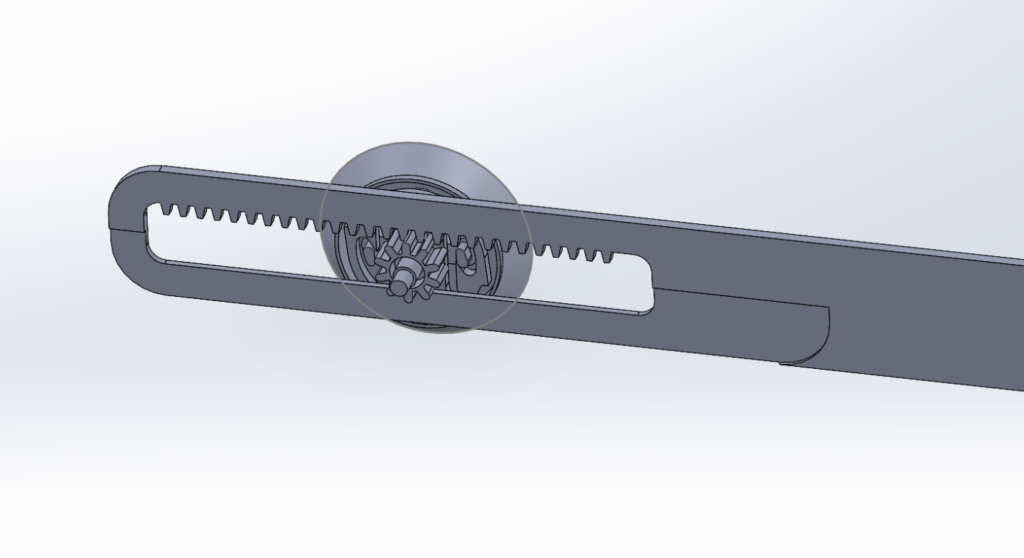

Assembled Adjustment Mechanism SolidWorks Model:

Adjustment system uses a double rack mechanism. This is the model used for proof of concept and simulation purposes.

Adjustment system uses a double rack mechanism. This is the model used for proof of concept and simulation purposes.

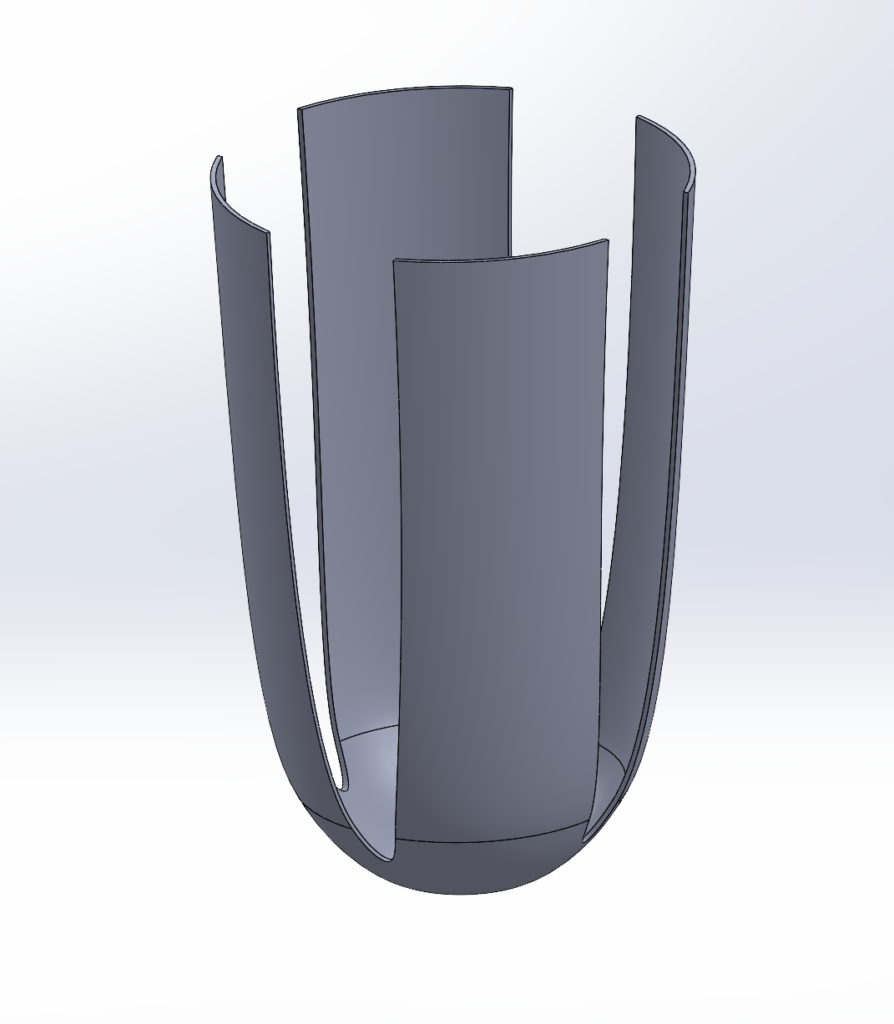

Base Socket SolidWorks Model (Isometric and Front View):

Note: the socket will be printed in its most expanded state for easier adjustment

Note: the socket will be printed in its most expanded state for easier adjustment

Preliminary Design Sketch: