September

- The team presented initial design requirements that peers and professors reviewed. These requirements were modified based off the feedback.

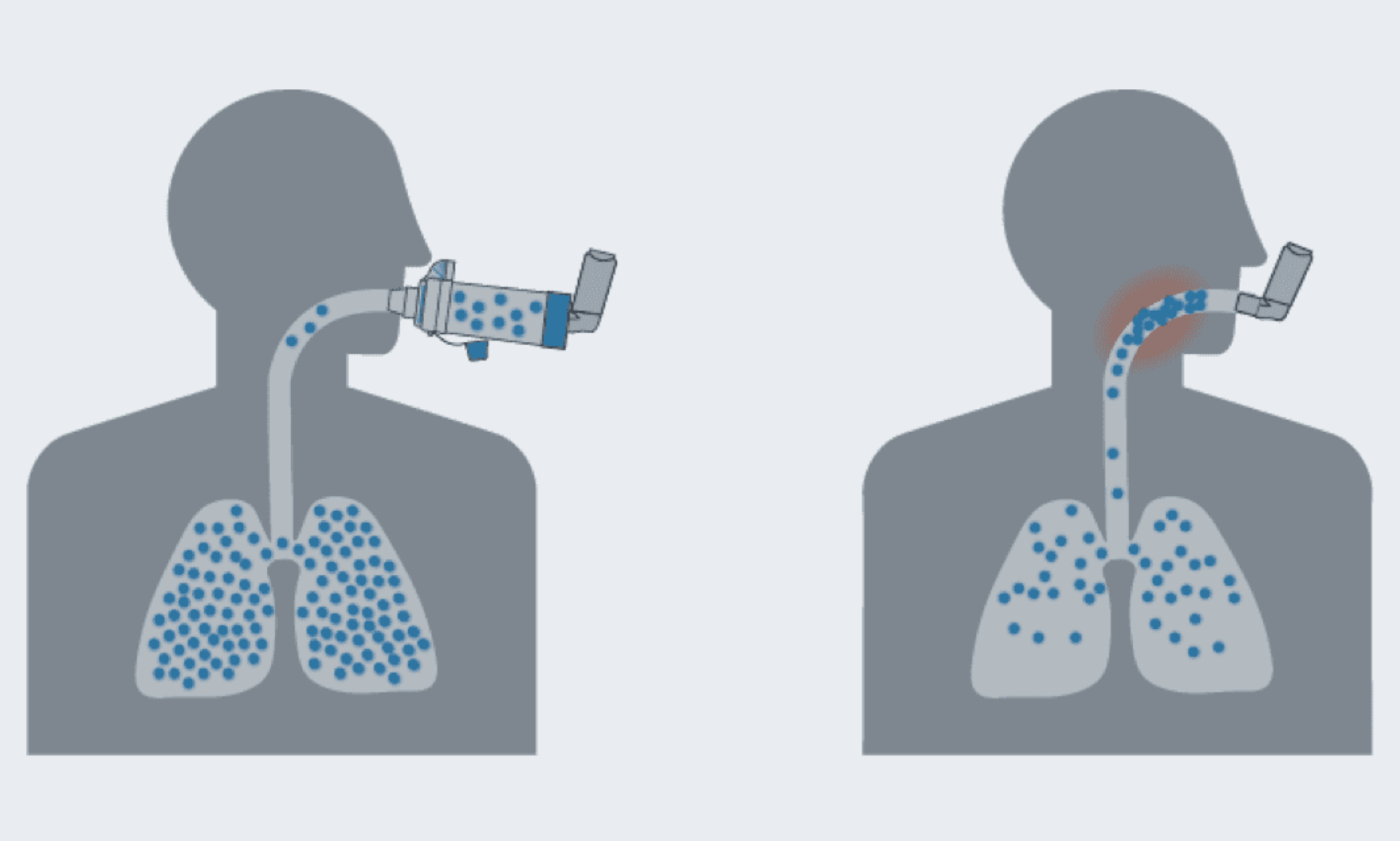

- The project shifted from designing a breath-actuated metered dose inhaler to a smart spacer system.

- Realistic constraints were created for the smart spacer system project.

October

- The team identified a list of standards that will apply to the project.

- The team finalized a budget for ordering parts such as a pressure sensor, a microcontroller, LED lights, and batteries.

- A Gantt chart was created to follow a timeline for when tasks should be completed.

- Three initial designs were created with the SolidWorks model.

- The team presented their interim design presentation.

November

- The team identified specific hazards that will be accounted for and maintained throughout the project.

- An abstract was created that highlights the main points of the project.

- The draft report was outlined with necessary deliverables.

- Decision matrices were created for the microcontroller, battery, differential pressure sensor, and 3D printing material.

- The team decided on a design (Design 1) to proceed with a 3D model drawing.

December

- The final design drawing was created.

- The team presented their final design and received feedback on their requirements, design solutions, verification and validation activities, decision matrices, and overall design of the device.

- The team completed their initial report draft for review.

January

- The team came up with a timeline for the upcoming semester.

- The team finalized their budget and placed orders for each part.

- NEBEC Abstract was created.

February

- NEBEC Abstract was adjusted and submitted.

- The team wrote preliminary verification protocols for every requirement.

- 3D modeling initial prototypes are being designed.

March

- Initial prototype was 3D printed.

- Verification testing was started.

- NEBEC poster was created.

April

- Final 3D prototype was printed.

- The team presented their poster at NEBEC.

- More verification testing and validation testing.

May

- Verification and validation testing completed.

- Final design model completed.

- Final presentation!