Film Sensor

In order to fabricate the electrode film sensor, a 2D array was designed in SolidWorks, ensuring all electrodes were equidistant. This array was designed to measure the impedance in three zones, which are most susceptible to pressure injuries.

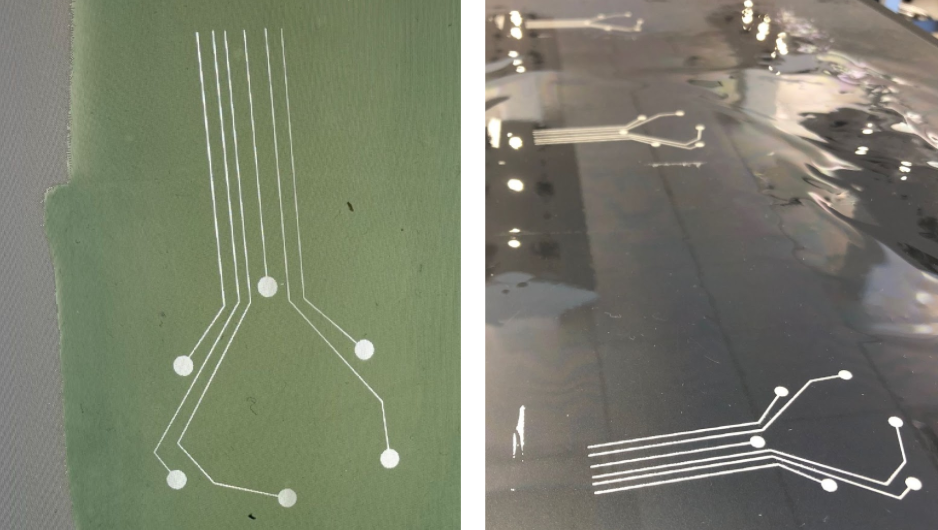

Once the stencil was finalized, it was printed on a piece of transparency paper and placed on hardened emulsion. The emulsion and stencil were exposed to light for 8 minutes and then rinsed out. What remained was the stencil, seen below, which was used to create various electrode sensing films.

Stabilization Component

The stabilization component was also designed in SolidWorks to bridge the gap between the conductive paste and the male-female pin connectors. The lid was designed to incorporate clips to hold the film in place, preventing the continuity from getting disturbed. Within this component, copper tape was used to extend the conductive lines and allow the male pins to be soldered to the single-use piece. The stabilization component designed in SolidWorks and the copper tape connection can be seen below.