Background:

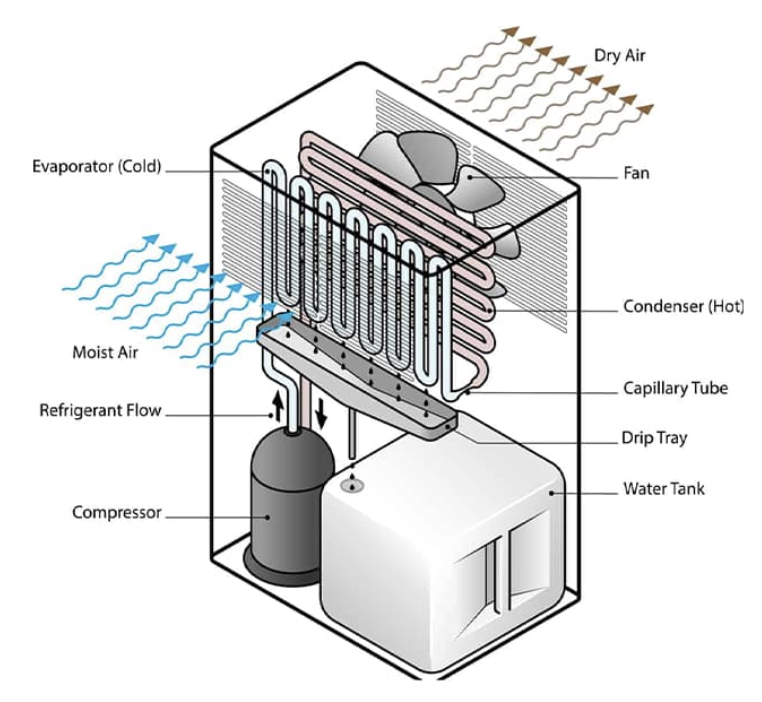

Traditional dehumidifiers typically use a refrigeration system, also known as the vapor compression cycle, similar to what’s found in air conditioners to remove moisture from the air. These dehumidifiers operate by drawing in air, passing it over cold coils to condense the moisture, and then reheating the air before releasing it back into the room. The condensed moisture is collected and drained away.

At lower temperatures, refrigerant-based dehumidifiers can face limitations in their efficiency. As the temperature drops, the efficiency of the refrigeration process decreases. These traditional dehumidifiers may struggle to extract moisture effectively in colder environments because the dew point—the temperature at which air becomes saturated and starts to release moisture—is closer to the temperature inside the dehumidifier. Consequently, they may not perform optimally in spaces with lower temperatures, like unheated basements, garages, or colder climates.

Desiccant dehumidifiers, on the other hand, operate on a different principle and are often more effective at lower temperatures. They use a desiccant material (such as silica gel or zeolite) to absorb moisture directly from the air. Unlike refrigeration-based dehumidifiers, desiccant dehumidifiers do not rely on the dew point to condense moisture. They work by adsorbing moisture molecules onto the desiccant material, which can still effectively remove moisture from the air even at lower temperatures.

This makes desiccant dehumidifiers a better choice for colder environments or applications where maintaining lower humidity levels at lower temperatures is essential. They’re often used in places like garages, storage areas, basements, or in climates where the temperatures can drop significantly or in our case vacation homes left unattended during winter months.

Figure 1: Traditional Dehumidifier

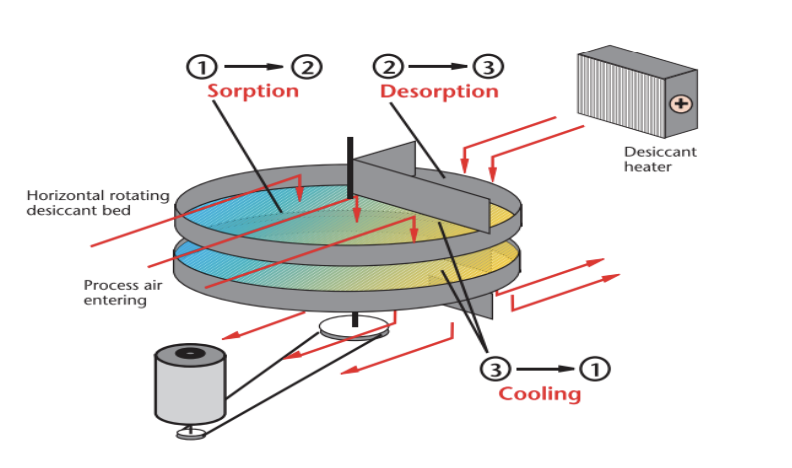

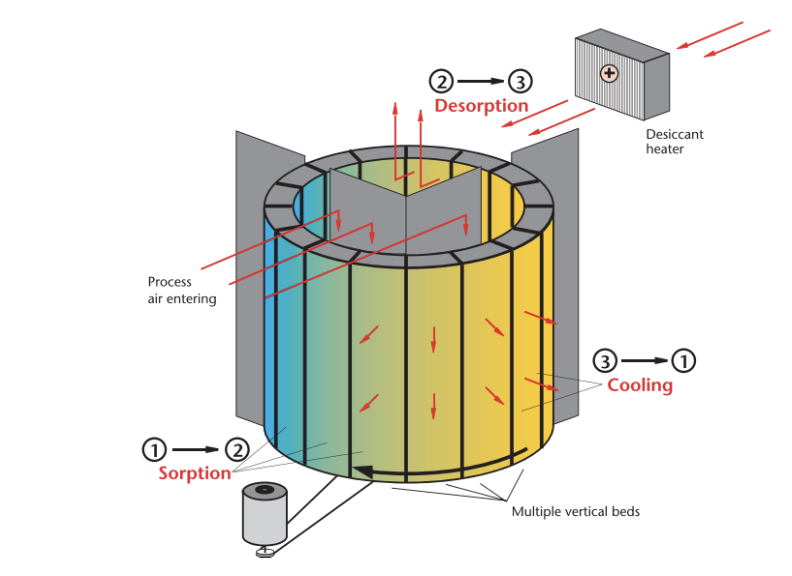

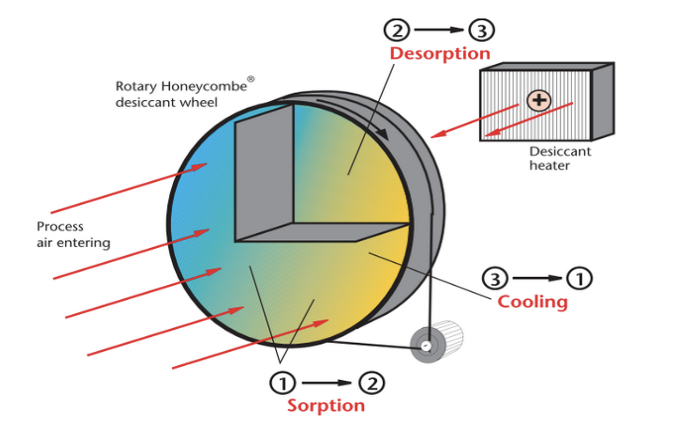

We initially had three desiccant dehumidifier designs in consideration, as seen below. Although we ended up going with the rotating desiccant drum design because it scored highest in the design matrix in terms of simplicity, cost, effectiveness and manufacturability. Moreover, we had three options in terms of desiccant materials: silica gel, clay and zeolite. Although type 1 silica gel proved to be the most efficient in terms of its high moisture absorption capacity and stability.

Figure 2: Rotating Horizontal Bed

Figure 3: Multiple Vertical Beds

Figure 4: Rotating Honeycomb

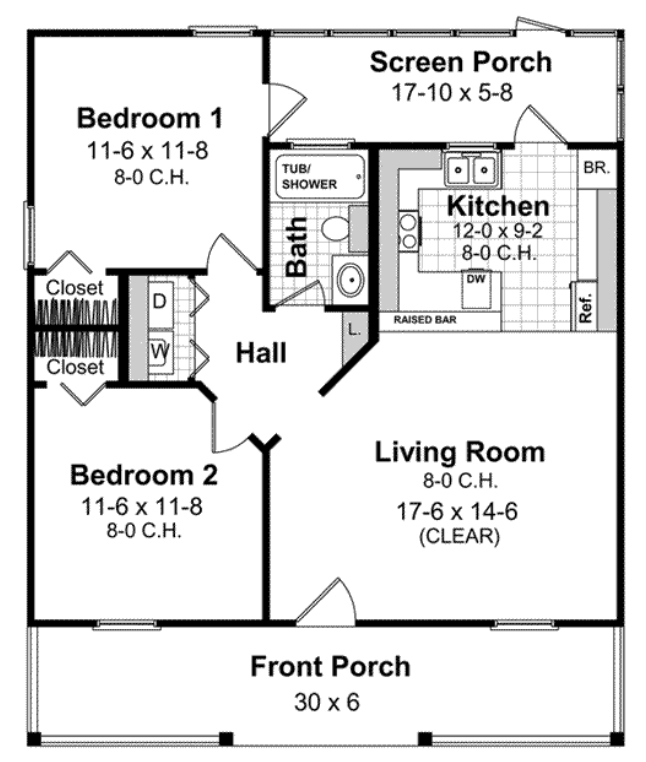

Figure 5: Typical 800 ft2 Floor Plan

This is ultimately a floor plan of a vacation home the desiccant dehumidifier would be used for during the winter months when it is left unattended to help prevent mold growth from excess moisture even at the lower temperatures.