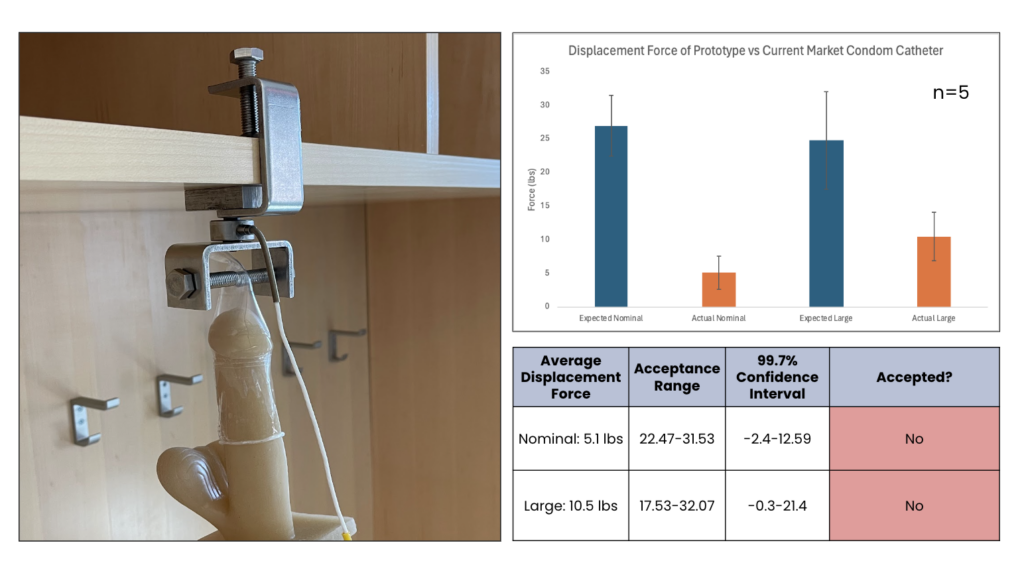

Verification 1.1 involved conducting force-displacement tests on anatomical models using three condom catheters of varying sizes. Five trials were conducted for each catheter size, and the average displacement force was measured using a load cell. Despite applying a 99.7% confidence interval, the mean value did not align with the acceptance range, resulting in a failed verification.

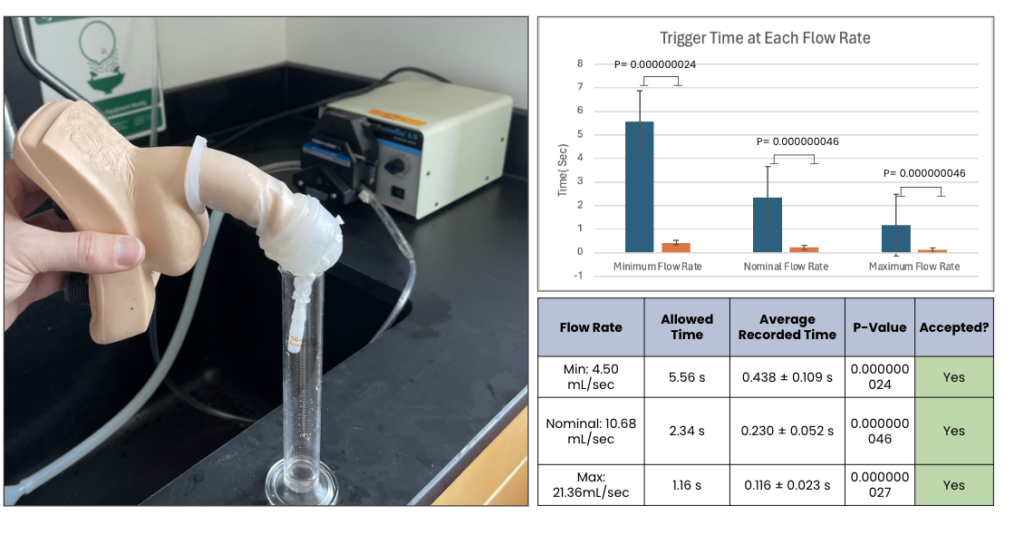

Verification 1.2 involved the assessment of the trigger times of the device under different flow rates. The setup involved attaching the respective components of the entire system with the use of a peristaltic pump to simulate the flow rates of urine. The modified catheter was placed on the nominal-sized anatomical model. Five trials were conducted for each flow rate, and the average time was calculated. After applying a 99.7% confidence interval, the mean value did align with the acceptance range, resulting in a passed verification.

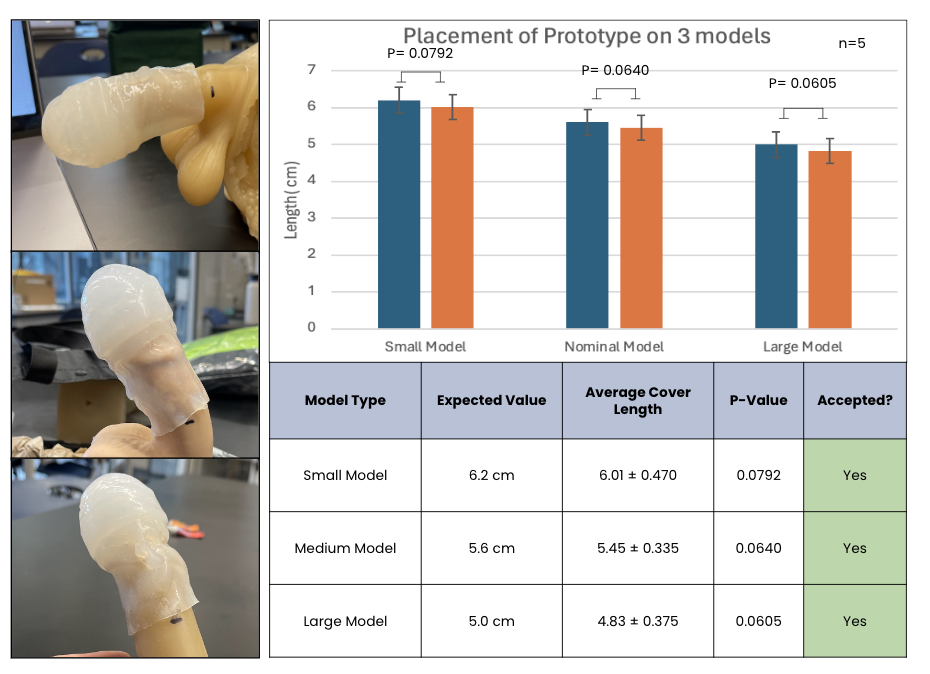

Verification 1.3 involved the assessment of the fit under different-sized anatomical models. Five trials were conducted for each sized model, and the average size measurement was calculated. After applying a 99.7% confidence interval, the mean value did align with the acceptance range, resulting in a passed verification.

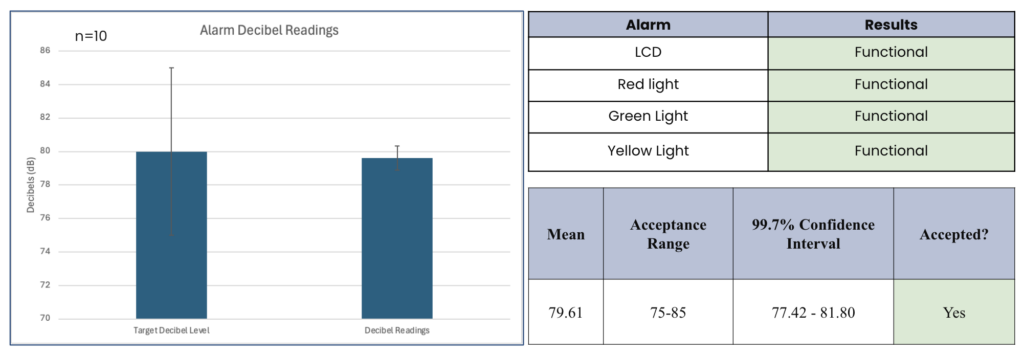

Specification 4 was verified by measuring the decibels of the audible alarm powered by 9 volts, ensuring compliance with the acceptance range of 75-85 dB using a 99.7% confidence interval. In addition, the functionality of digital display, and audible and visual alarm systems was completed.

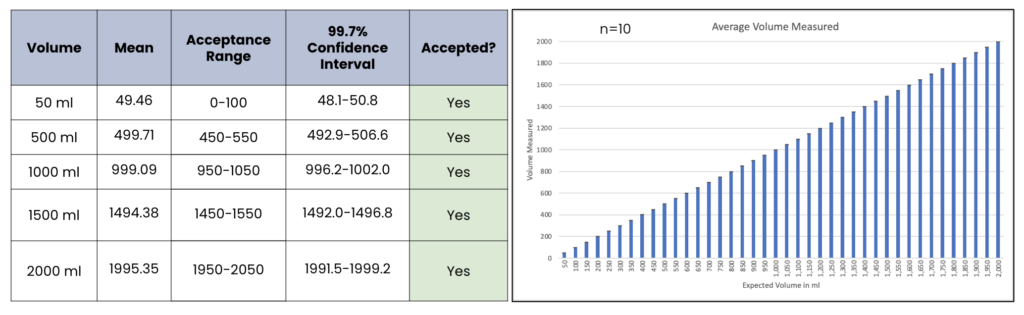

Specification 5.1 was verified by measuring volume every 50 mL, ensuring compliance with the acceptance range using a 99.7% confidence interval. Although only five volume levels are provided, all ranges fell within the confidence interval. Specification 5.2 entails the verification of alarm systems.

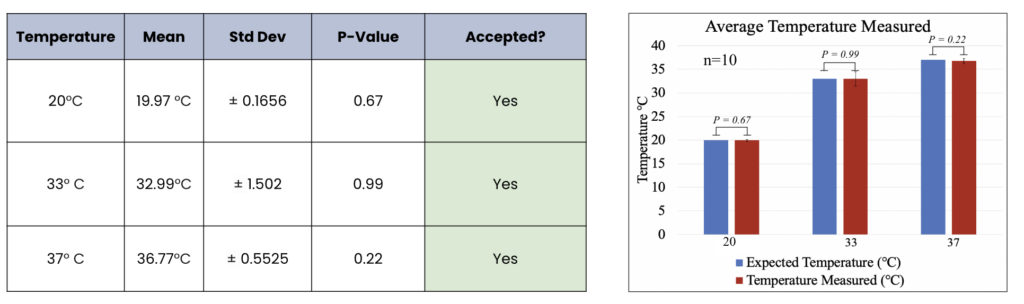

Specification 6.1 verification was confirmed through temperature measurements taken at three distinct levels: 20°C (Room Temperature), 33°C (Skin Temperature), and 37°C (Body Temperature). To ensure accuracy, a one-sample two-tailed t-test was employed to compare the thermistor measurements, aiming to detect any statistically significant differences. Results from the statistical analysis revealed that the acceptance criteria were satisfactorily met as there was no statistically significant difference.

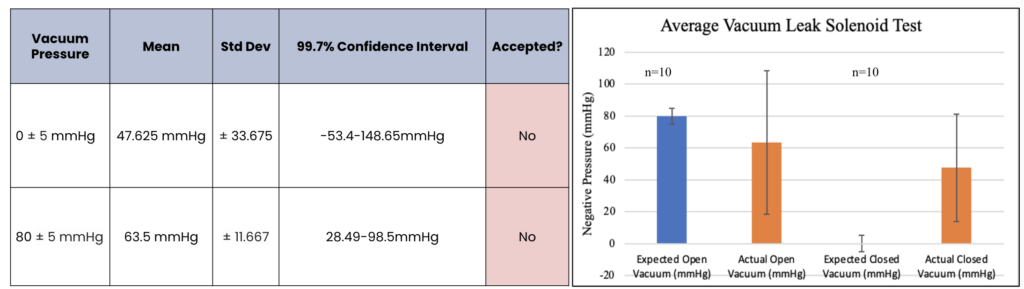

Specification 6.2 underwent testing via the measurement of negative pressure applied at the attachment site. With the solenoid open, an anticipated pressure of 80 mmHg was expected, while a closure of the solenoid was anticipated to yield 0 mmHg. Employing a 99.7% confidence interval, an acceptance range was established. However, statistical analysis revealed that the acceptance criteria were not met, indicating a failure to comply with Specification 6.2. The failed verification is due to a leakage present in the system, specifically the solenoid valve.

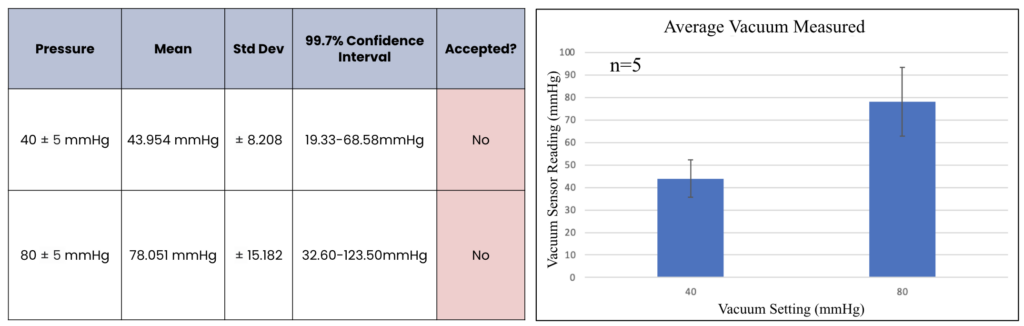

Specification 7 underwent testing by measuring negative pressure at specified thresholds of 40 ± 5 mmHg and 80 ± 5 mmHg. Following the establishment of an acceptance range using a 99.7% confidence interval, statistical analysis was conducted. However, the results indicated that the acceptance criteria were not met, signifying a failure to comply with Specification 7.

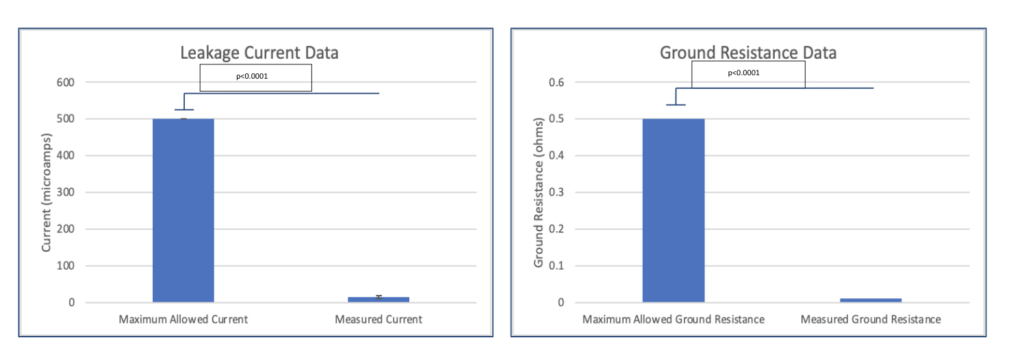

Verification 10 involves employing an AC-reading multimeter to conduct 10 measurements each for leakage current and ground resistance. The acceptance criteria entail performing a one-sample, one-tailed t-test. Upon analysis, both populations were found to exhibit significantly lower values compared to industry standards.

Additional Specifications

| Specification 8 | Verified in volume detection (Specification 5) |

| Specification 9 | Verification in part selection |

| Specification 11 | Verification in part selection |