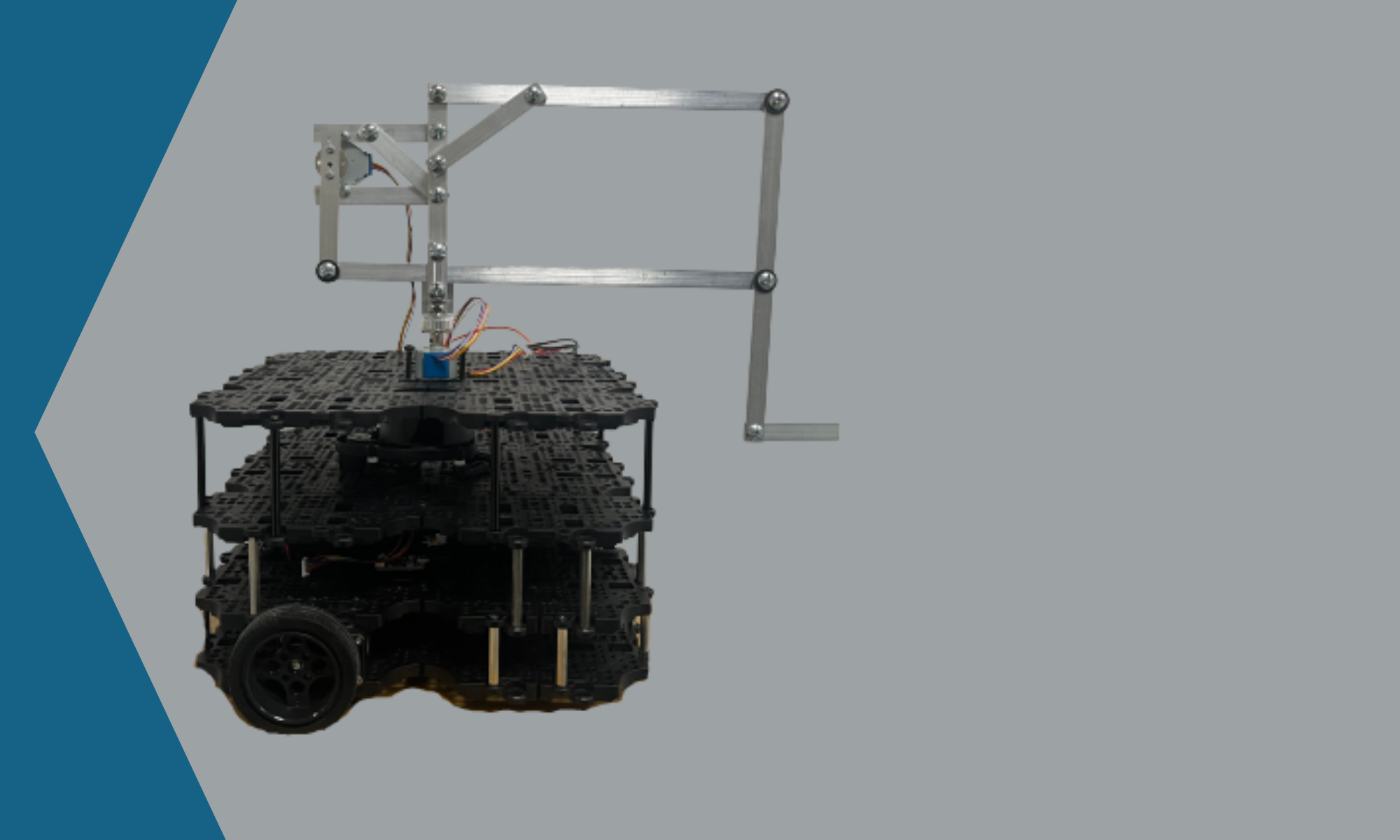

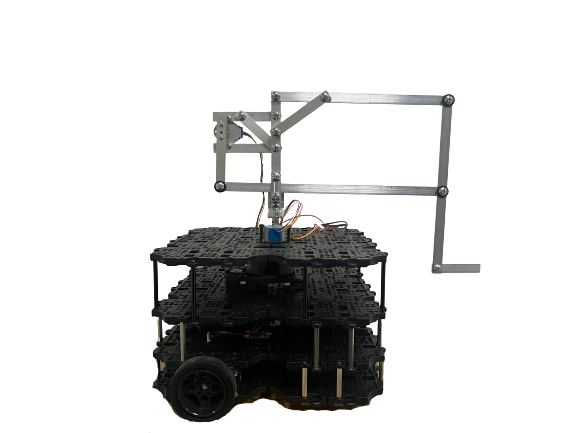

The mechanical arm design was drafted using AutoDesk’s AutoCAD. The dimensioned front and top views can be seen in Figure 10 and Figure 11 respectively. Figure 12 provides the front in top views of the mechanical arm without the dimensions. The main challenge of this design was the incorporation of the two stepper motors. In order to mount the motor the mechanical arm, a universal mounting hub was used. The universal mounting hub is connected to the shaft of the motor and provides a flat surface for the motor to be mounted. Mechanical advantage was used for the motor responsible for the push/pull motion.

Construction of the mechanical arm took place in the STEM Building Machine Shop with the assistance and supervision of Joe Zanetti. The main material used for the mechanical arm is aluminum. This material was selected for its lightweight and strength properties. Aluminum pieces were connected via captured fasteners. Fiber washers were placed between the captured fasteners and the aluminum of the moving joints. Two pieces were custom made to provide stability to the arm. Additional supports were added to strengthen the overall design.

Fig.10 Dimensioned Front View of Mechanical Arm

Fig.11 Dimensioned Top View of Mechanical Arm

Fig.12 Front View and Top View of Mechanical Arm without Dimensions

Final Mechanical Arm on Turtlebot