When we started our project we had the idea to create a half-scale prototype of our final design. We have learned several things from creating this prototype, which will help us create a more elegant final product.

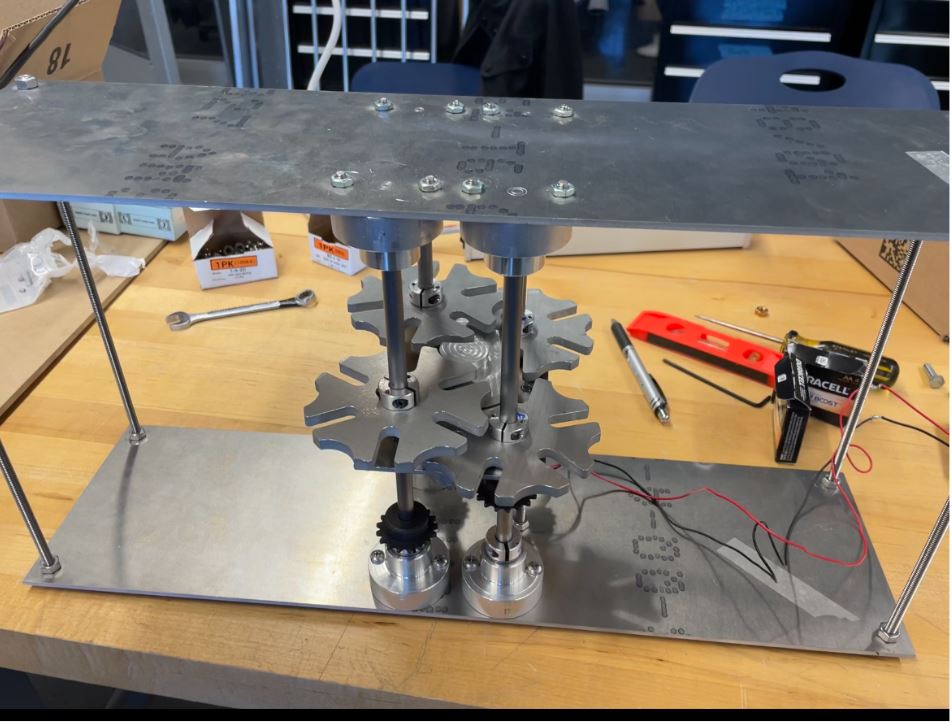

The geneva mechanism used to rotate the shafts can be seen on the left. All of the pieces created were machined using TCNJ facilities.

In our miniature prototype, we framed our mechanism in order to provide better structural support. This experience taught us the importance of tolerances and alignment in order to prevent the mechanism from seizing during its rotation. In order to address this in our full-scale prototype we plan on water jetting the top and bottom support plate simultaneously.

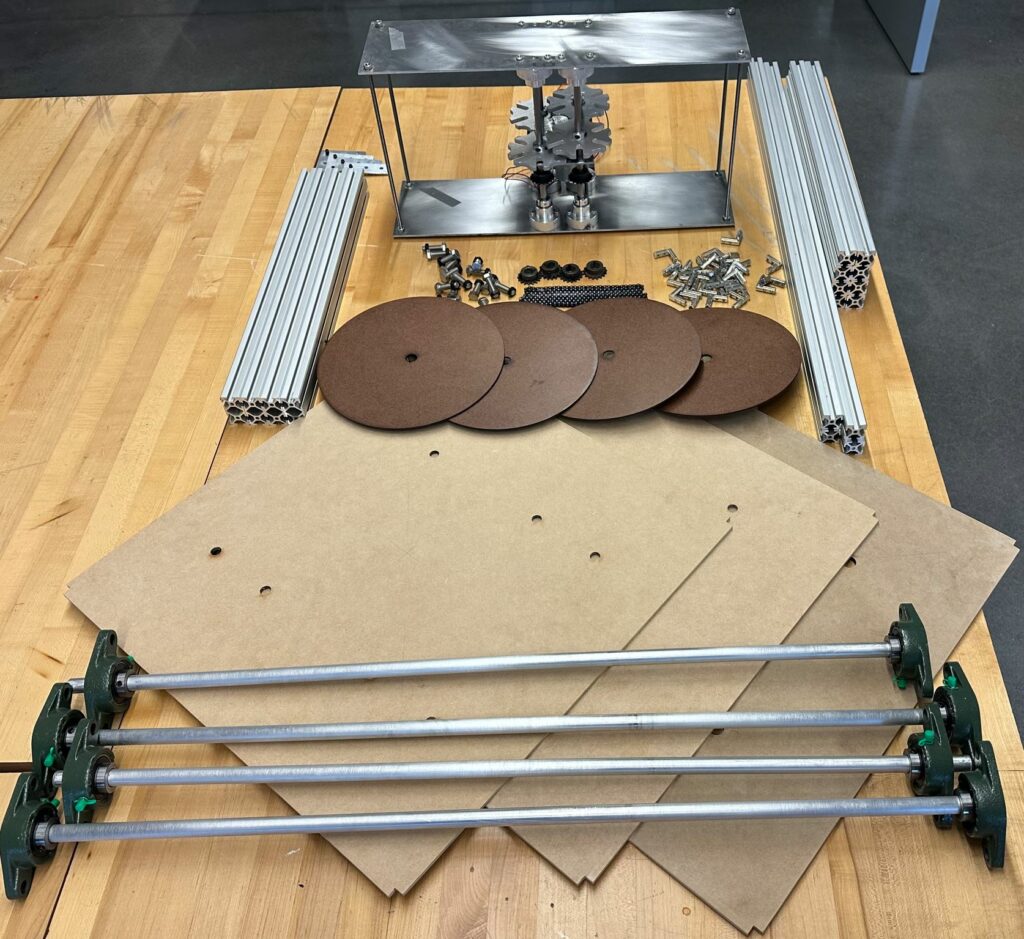

A lot of pieces were required to create our miniature prototype. All of the pieces can be seen in the graphic on the left. All these pieces were either purchased or machined using the TCNJ facilities.

Seen here is our completed miniature prototype. This prototype has four adjustable shelving units in order to display smaller items of importance for the school of engineering. This prototype helped prove our design is functional, as well as provided important insight into changes for the full-scale model. For example, the wood supports with be broken up into four pieces, improving the alignment of the case, as well as allowing them to be laser cut.