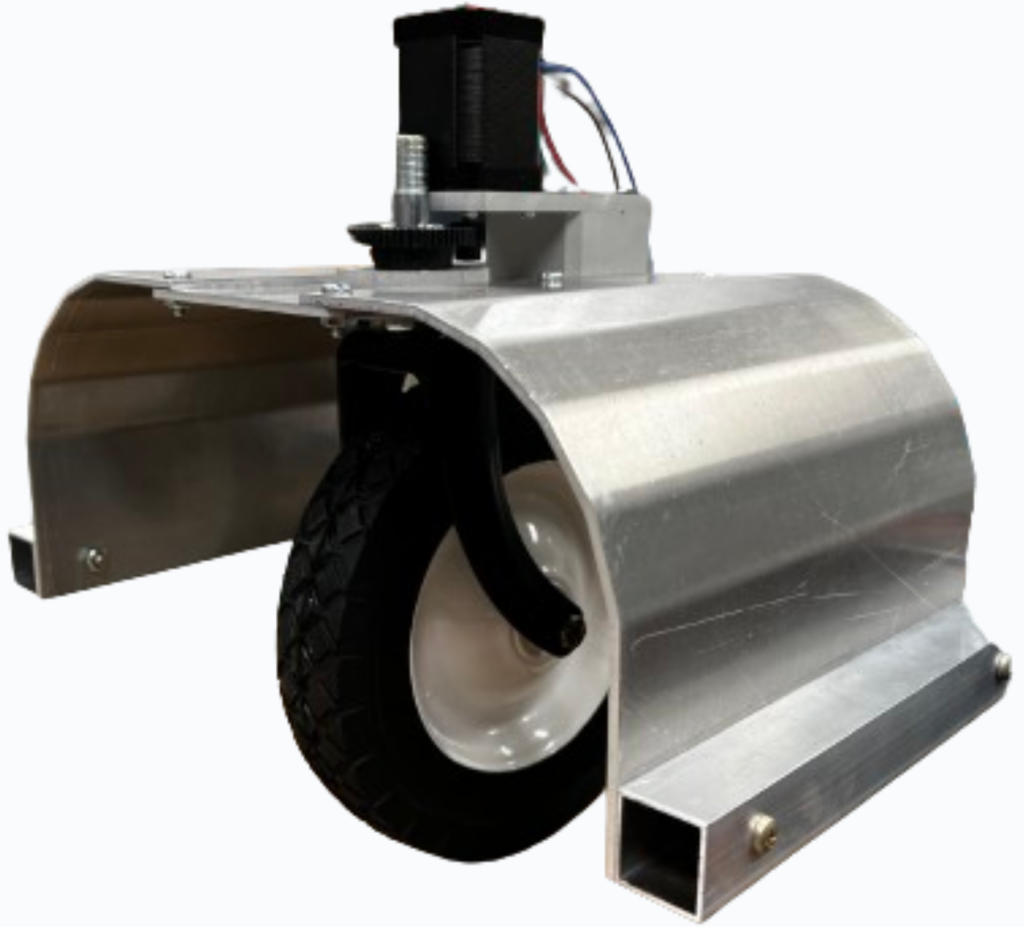

The material of the base plate of the vehicle will be Aluminum 6061. The size of the base plate will be 99.44cm x 60.96cm x 0.1cm (LxWxD). We are using three, eight inch wheels, two in the back and one in the front. The two rear wheels will require a nine inch by three inch cutout of the baseplate to allow for mobility. The front wheel will require a 22.86 cm by 22.86 cm cutout to allow the front wheel to turn 45 degrees left and right. To improve balance, we will be adding caster balls to left and right of the front wheel.

Figure 1. Autocad drawing of the vehicle baseplate and support

Other components placed ontop of the baseplate will be the front motor and gears for the steering of the front wheel, a pannel and four buttons for steering, the NAO robots seat, as well as, the microcontroller, battery, and rear gear for the driving of the back wheels.

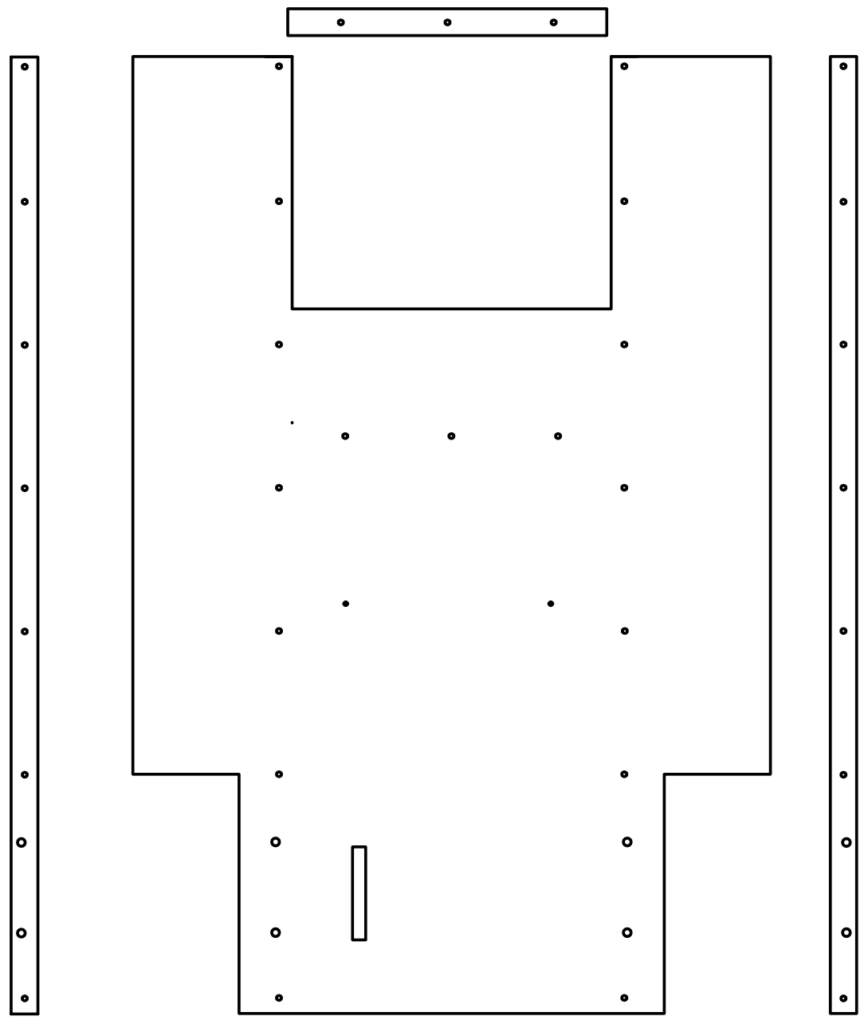

For the front wheel, the wheel fork has a 2.75 inch long shaft coming out the top of the fork. If we were to align the top of the shaft with the base plate the car would take on a drastic upward slant. This would affect the sensors ability to sense objects infront of the vehicle. To mitigate this issue, we will build a shelf where the front wheel can sit aligned on the same plane with the back wheels and the wheel fork shaft will be above the base of the car. On top of the shelf will sit the stepper motor and attached gears that turn the front wheel.

Figure 2. Front wheel controlled by stepper motor