September

- Design inputs were presented to peers and faculty advisors for feedback, then refined based on their suggestions.

- The team developed relevant project constraints and addressed any new device requirements that emerged as a result.

October

- The team identified applicable standards for the project and created a Gantt chart outlining the task completion timeline.

- A preliminary budget was finalized for ordering project components, including electronics, materials, reagents, and miscellaneous supplies.

- Flowcharts were created to map out the device’s functionality from both the user’s perspective and its internal processes, helping to streamline overall operation.

- The team has entered the initial phase of developing potential design concepts for the project.

- Specifications and verification activities for the design inputs were determined.

- The team presented their interim design presentation and received feedback from peers and faculty.

November

- A hazard analysis was conducted to address any risk associated with the project.

- The team is making final decisions on project components so that parts can be ordered and manufacturing can begin.

- The team finalized the abstract for the project.

- Revisions were made to design inputs for the final design presentation of the Fall 2024 semester.

- The treasurer began to order materials and device components.

December

- The team presented their final design review for the semester!

January

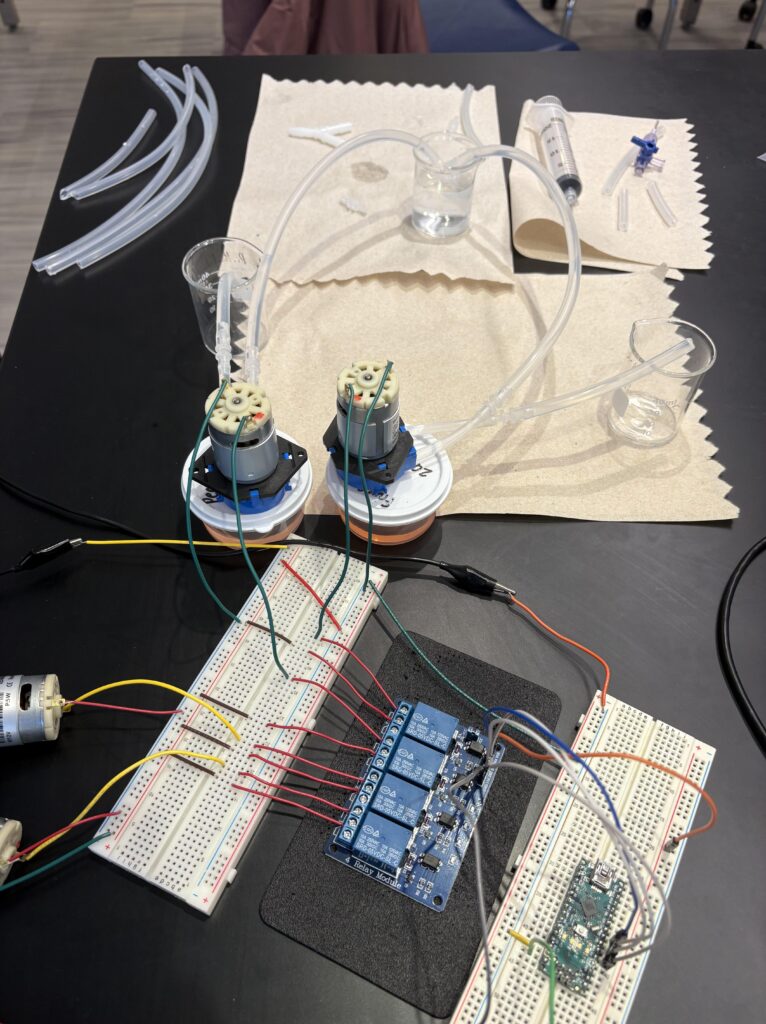

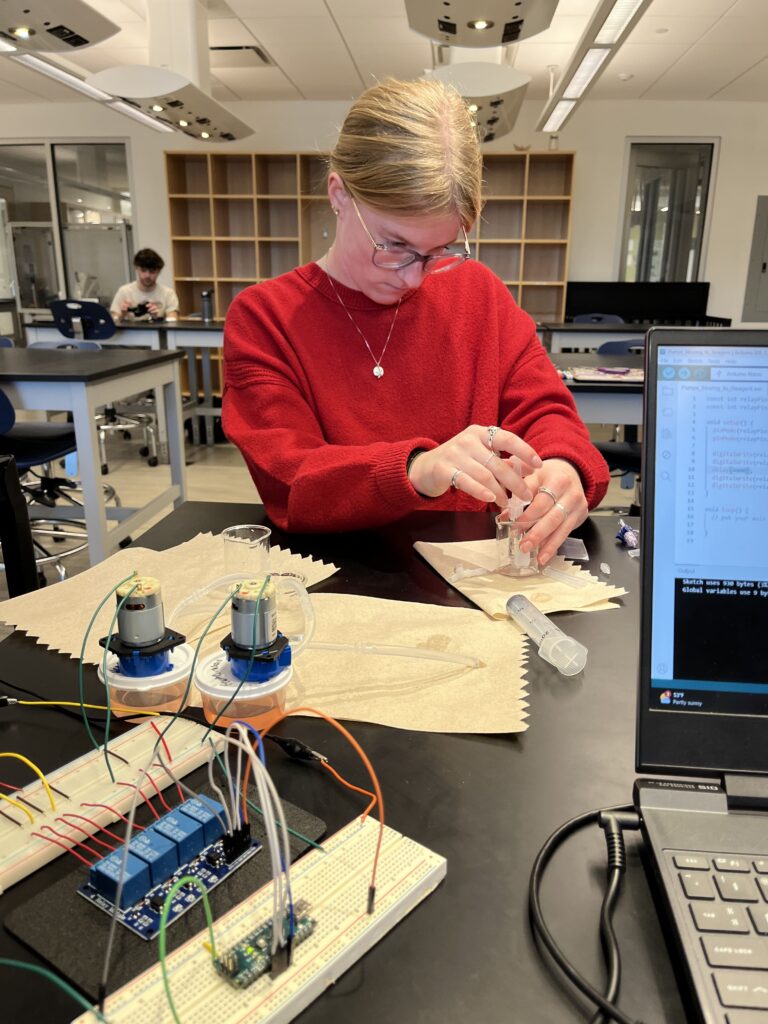

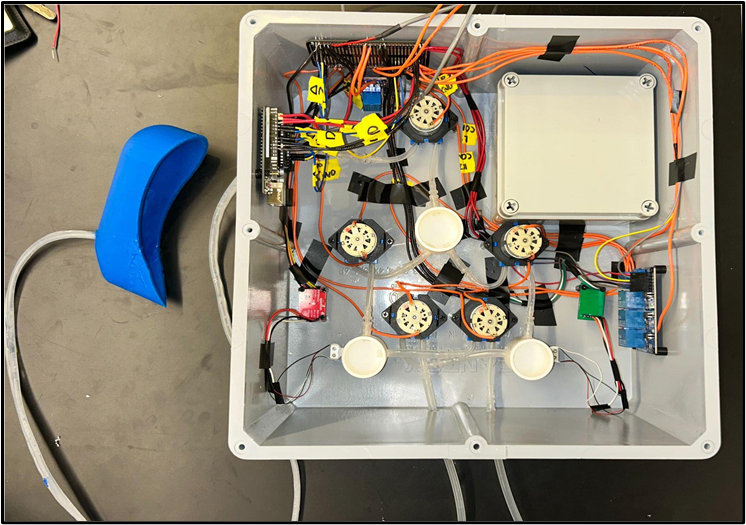

- Manufacturing of the device has begun, including microfluidics and peristaltic pump control via microcontroller.

- The team is actively writing and revising verification and validation protocols for the device.

February

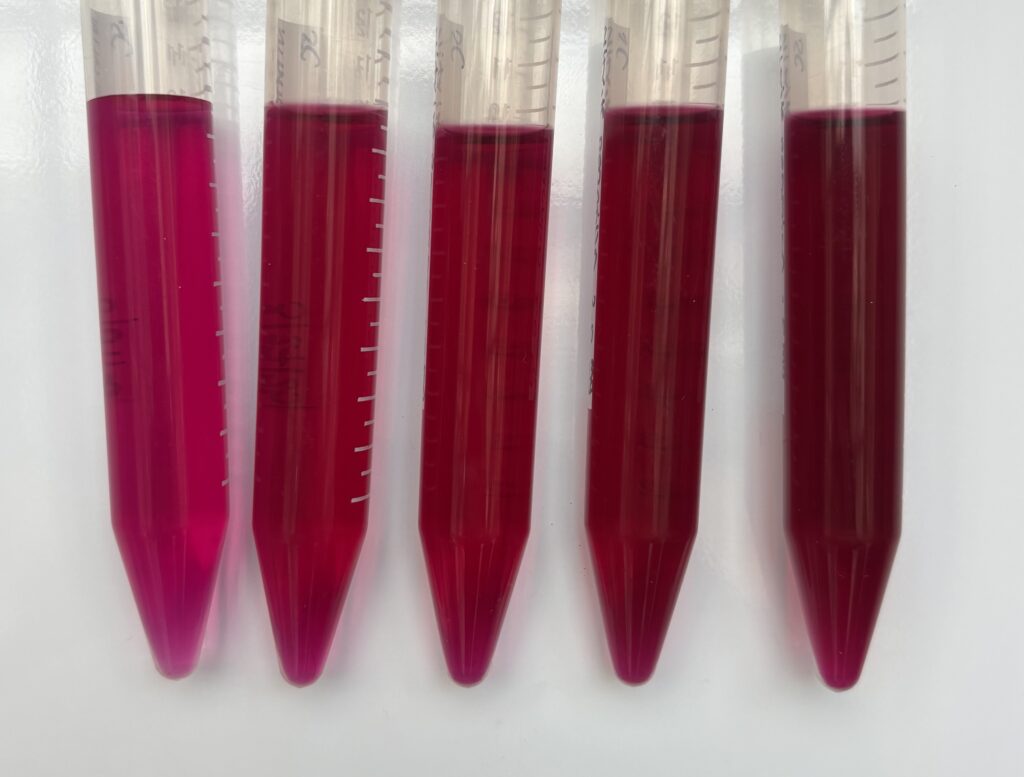

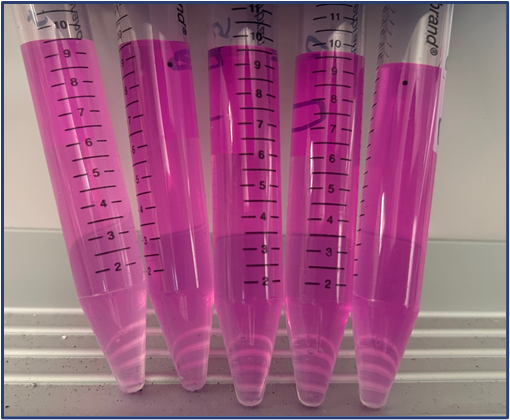

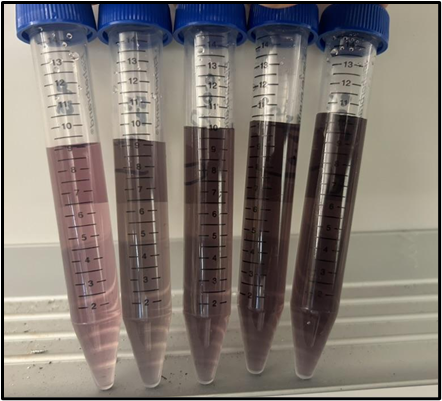

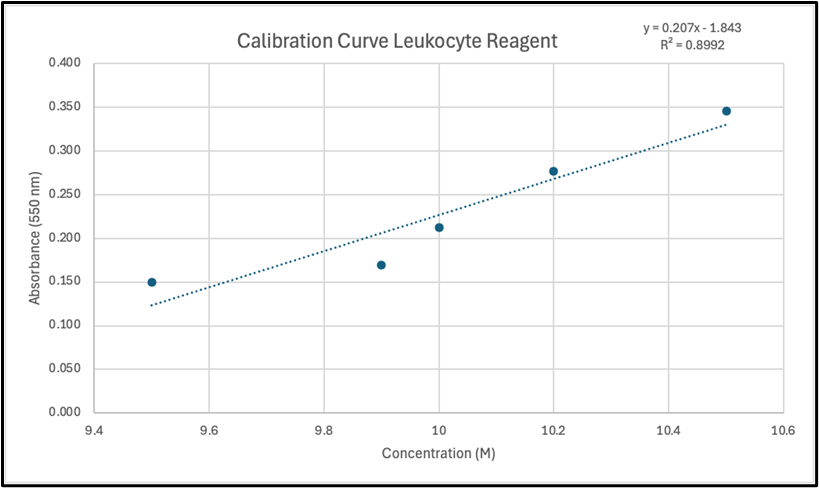

- Sara has begun running the protocols for leukocyte and nitrite reactions.

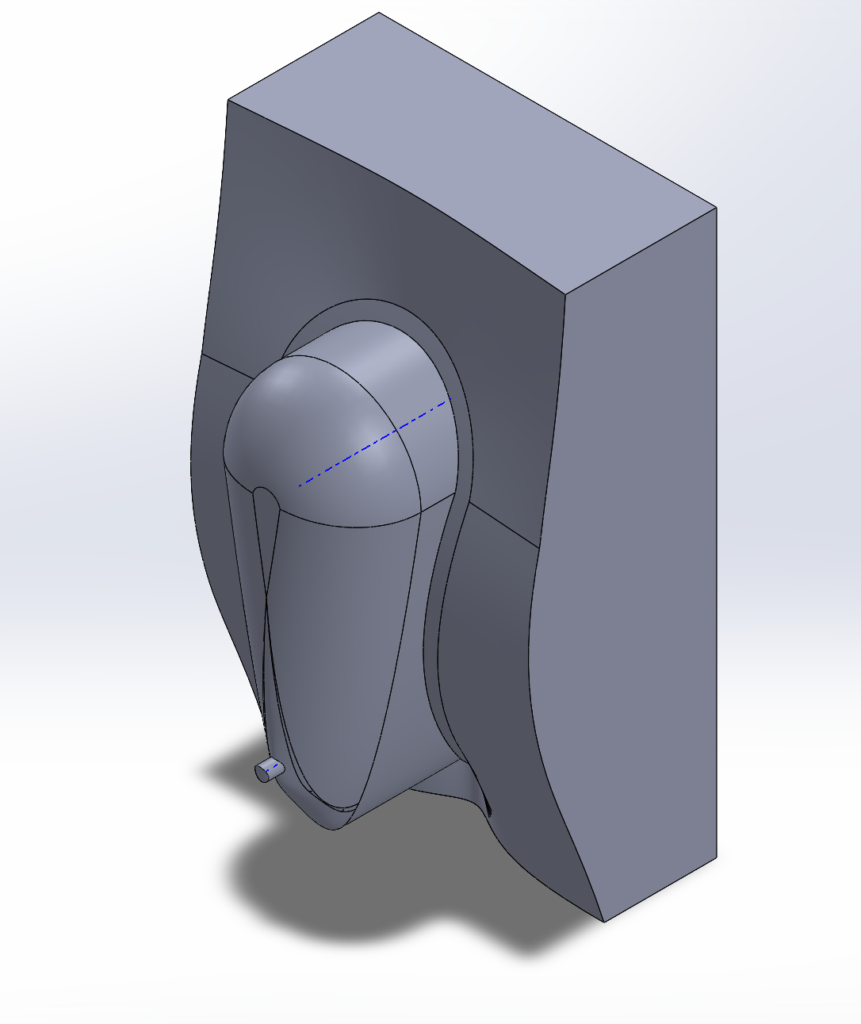

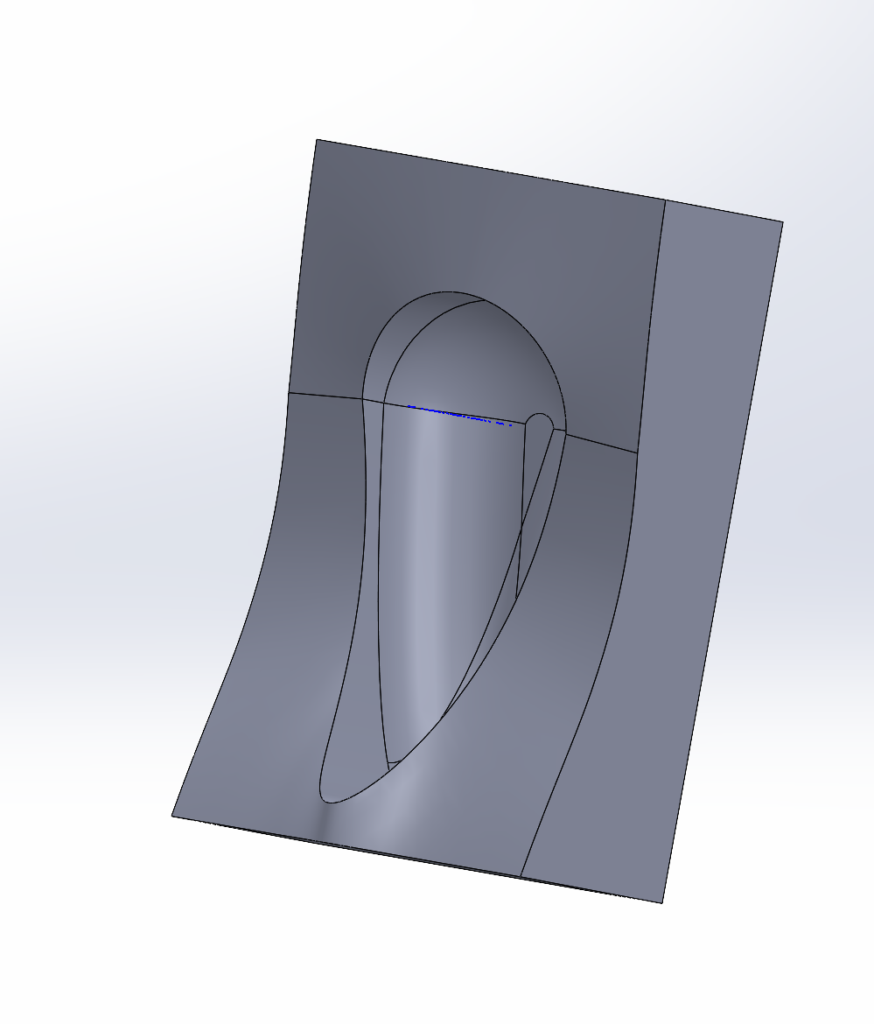

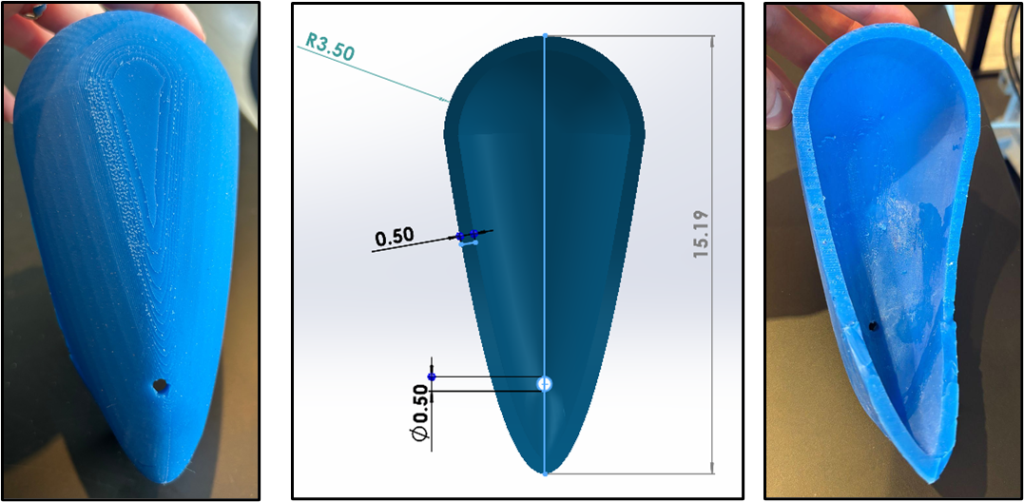

- Jon has sent the mold for the urine collection cup for 3D printing, and is finalizing the CAD model of the control box.

- Erin is working on the microfluidics of the urine transport from the urine collection cup to the control box, and how to split the sample for urinalysis.

- Iman is testing the colorimetric sensors for urinalysis as well as the load cells for volume readings within the control box.

March

- Jon 3D printed the urine collection cup out of Agilus material with a shore hardness of 30A for proof of concept.

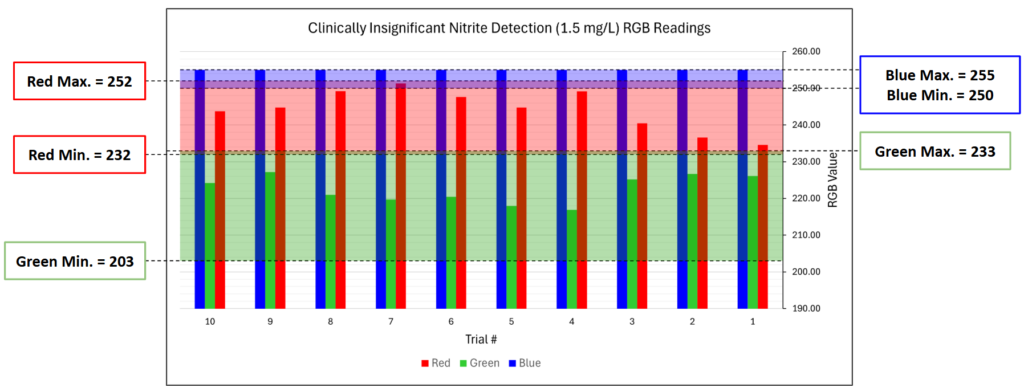

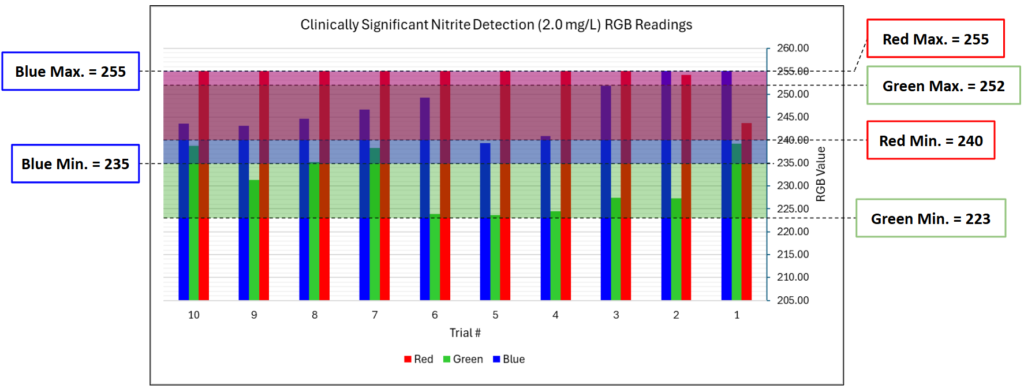

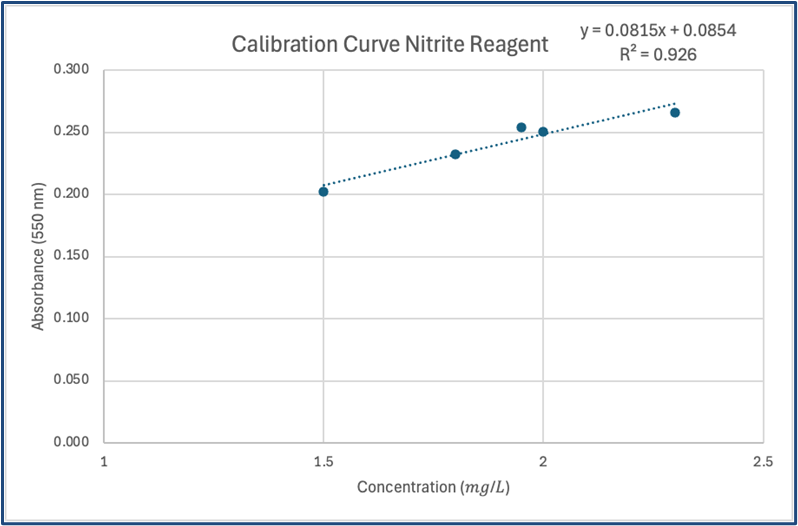

- Sara worked on the Nitrite reagent testing and developing calibration curves.

- Jon has also completed the press fit mold of the urine collection cup for silicone molding, and the urine sample compartments for within the control box, and has sent it for 3D printing.

- Iman calibrated the colorimetric sensor to run verification tests with Sara’s Nitrite reactions and achieved 20/20 accurate detections.

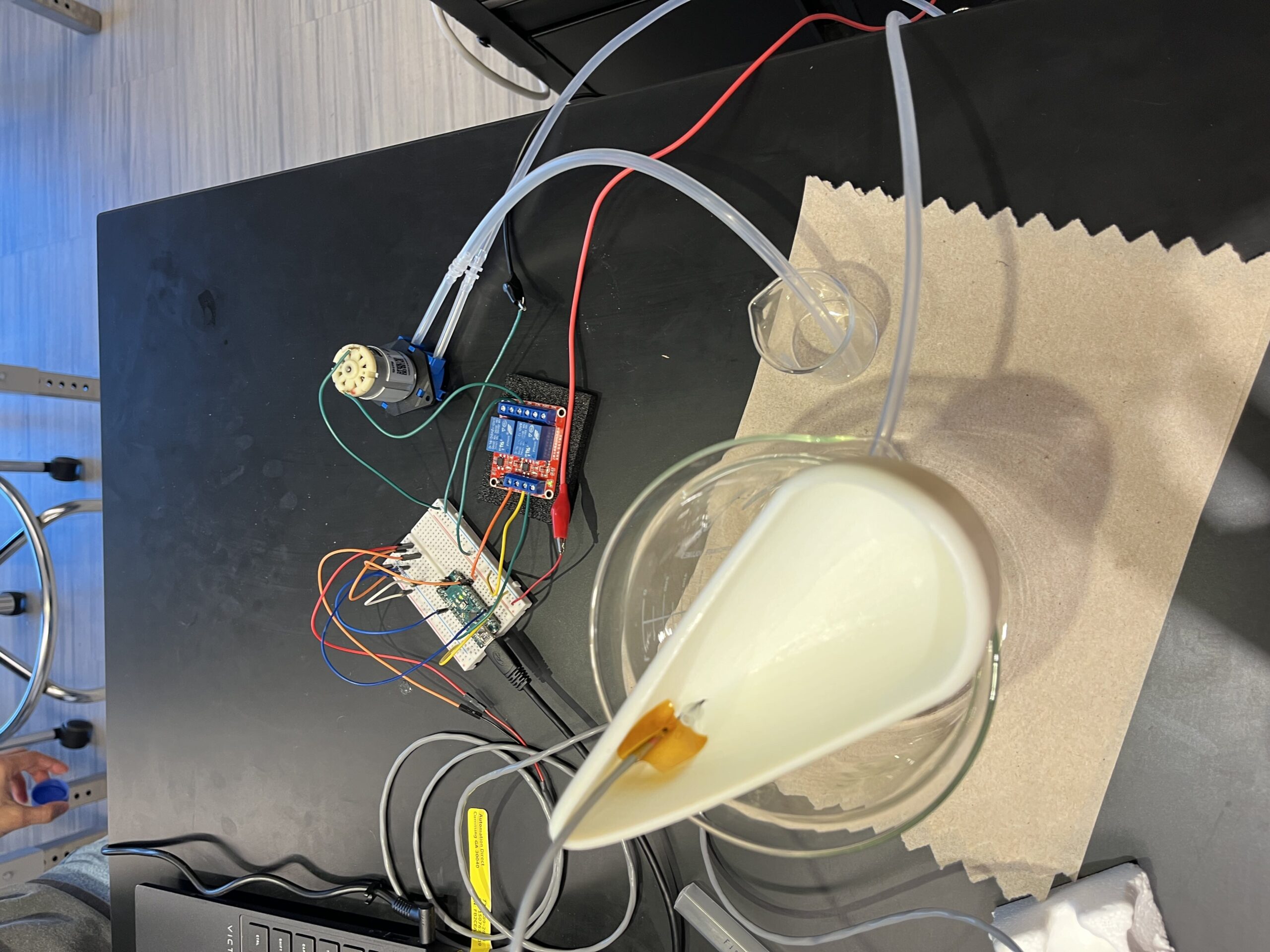

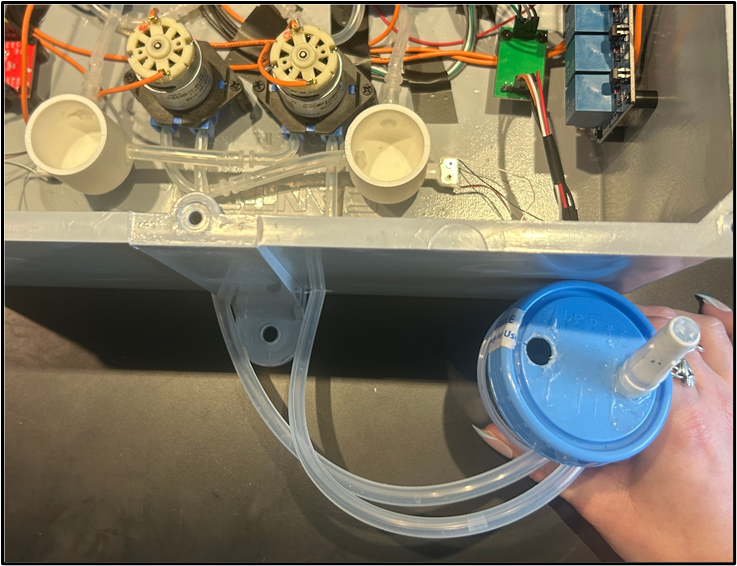

- Iman and Erin are actively working to finalize the urine sample transport throughout the control box through the manipulation of peristaltic pumps.

- Iman has finalized the initial detection of the urination cycle using a thermistor in the urine collection cup.

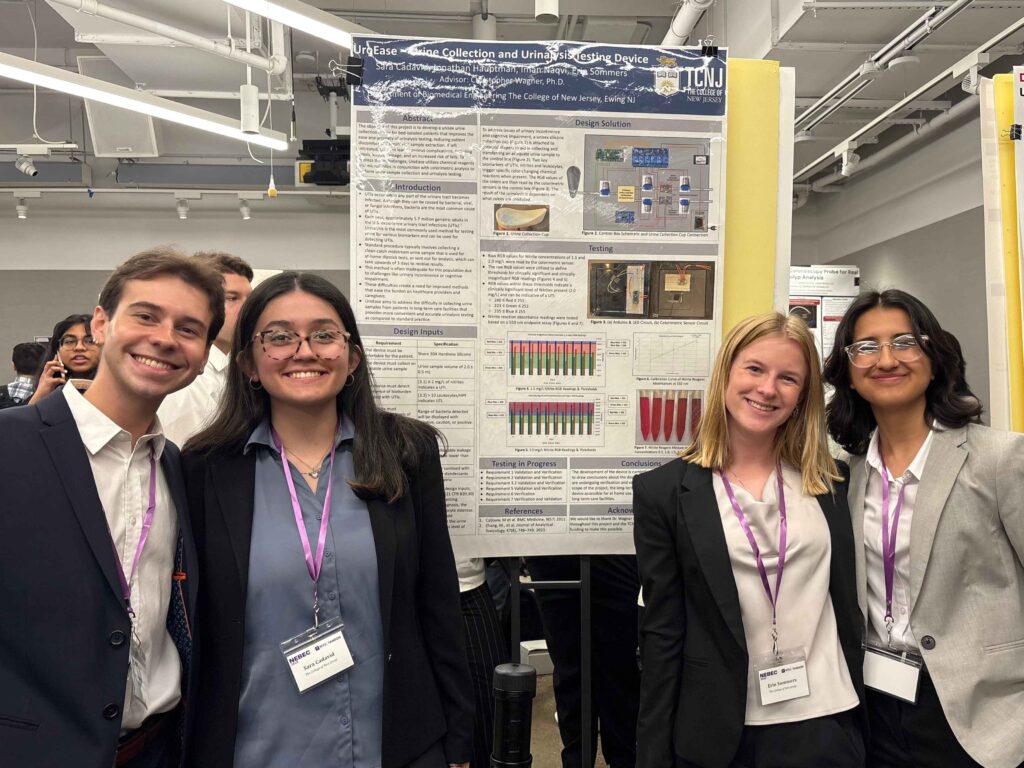

- The team was also fortunate enough to present their progress so far at NEBEC 2025 hosted by NYU Tandon School of Engineering!

April

- The team spent all of April assembling the device, as well as conducting verification and validation testing.

- The urine collection cup was silicone molded.

- The thermistor and tubing was fixed inside the cup.

- The nitrite and leukocyte reactions and concentrations were finalized.

- The final classification method for the leukocyte and nitrite reactions was determined as RGB classification with decision thresholds based on centroids and delta-values.

- The cleaning sequence was implemented using two additional peristaltic pumps and a external biohazard waste collection cup.

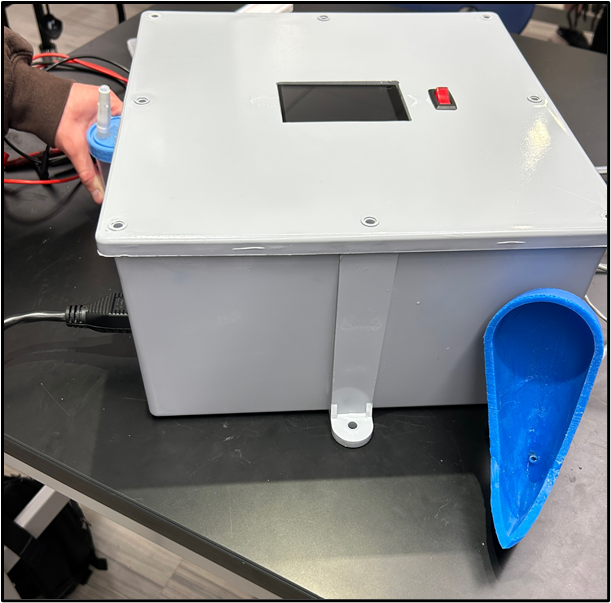

- The assembled device can be seen below!

The team is extremely grateful to Dr. Wagner for his advisement throughout the school year, as well as the other BME faculty and our peers. We’d also like to thank The School of Engineering for their financial support.