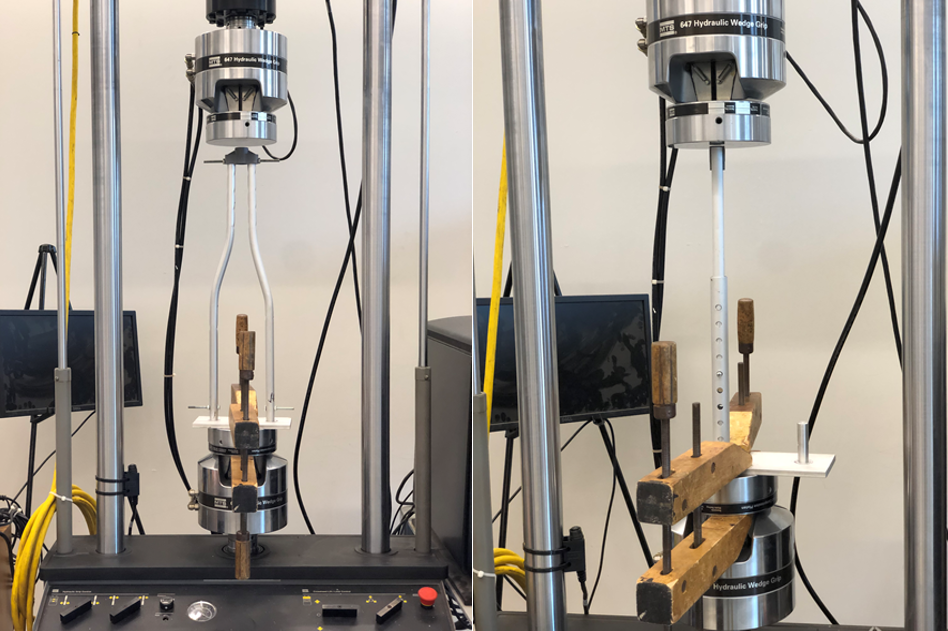

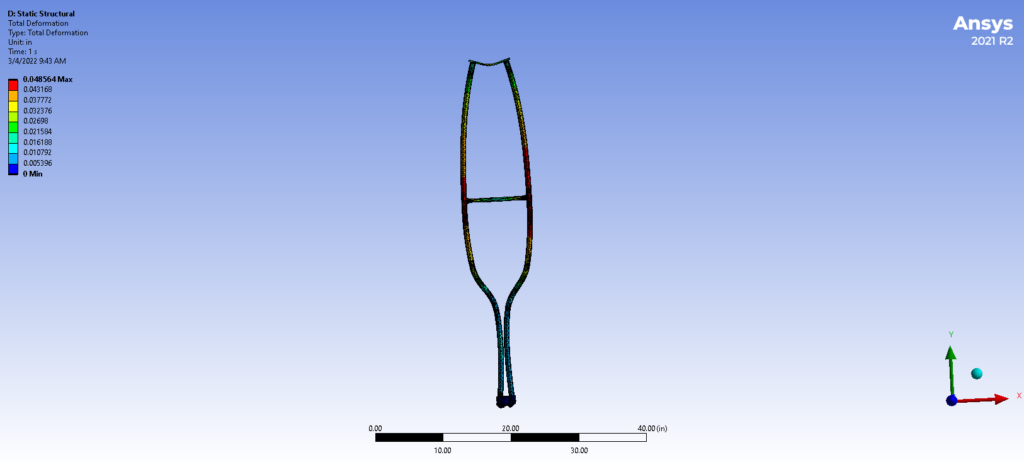

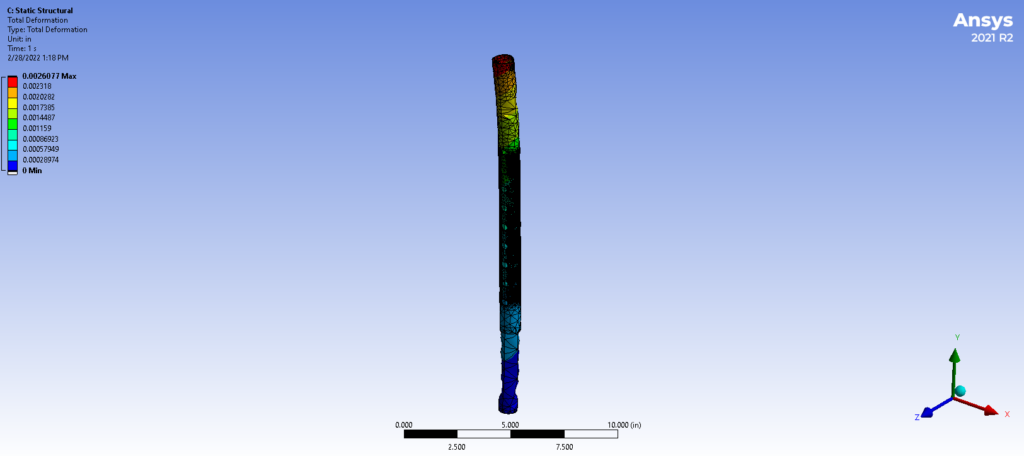

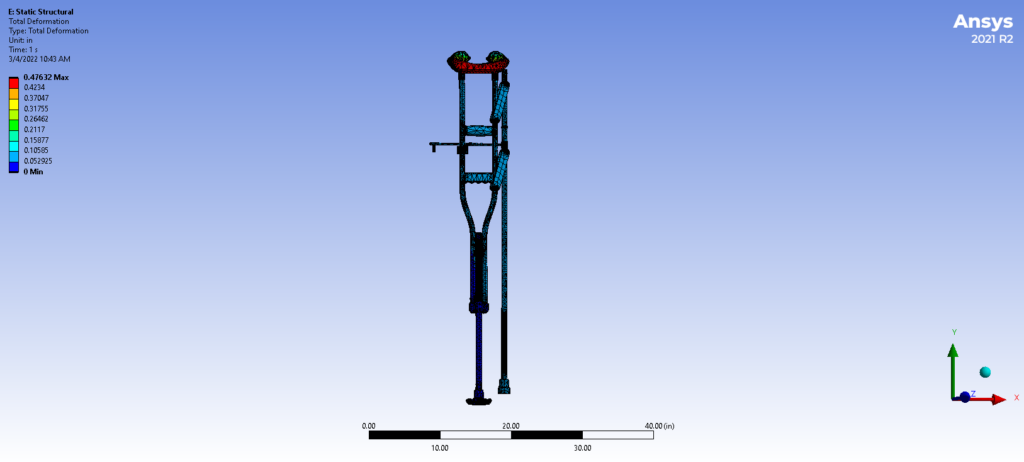

Since the device was too large to fit into the MTS 810 Material Test System, another strategy was developed to show the device could withstand the maximum weight specification. First, the validity of the relationship of the whole being equivalent to the sum of its parts needed to be demonstrated. This relationship was shown not to be true when summing the individual deformations of each section and comparing it to the deformation of the whole axillary crutch in the ANSYS simulation. However, when testing the crutch sections in reality, the summed deformations were shown to be not significantly different (p > 0.05) from the ANSYS whole axillary crutch deformation using a t-test with a power of 84.29%. Upon performing a test for normality, it was seen the distribution was not normal. As a result, a one-sample Wilcoxon test was performed which once again showed that no significant difference existed between the projected total deformations and the total vertical deformation of the simulated axillary crutch in ANSYS. Additionally, the total vertical deformation of the simulated device design in ANSYS (12.10 mm) passes the acceptance criteria which is deforming less than the specified 40 mm. While this data makes it appear that the device will pass, it ultimately fails the study because a definitive conclusion cannot be drawn regarding the validity of the relationship relating the individual deformations to the total deformation. More testing and research is needed to determine the true relationship between the individual deformation of each section and the total deformation of the crutch as a whole.