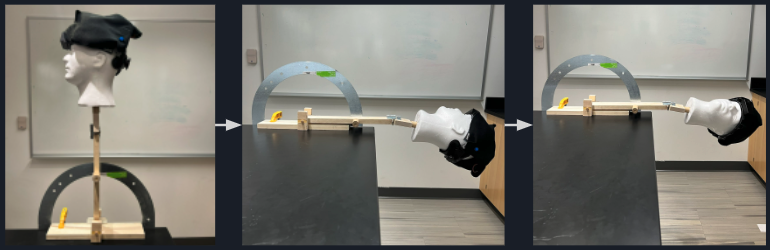

Testing Frame

Through the verification and validation testing of the Epley Maneuver System, we were given the opportunity to create a complementary tool exclusively for testing this device and ensuring that it works as stated. The frame is easily adjustable and manipulated to mimic the position of a person performing the Epley maneuver.

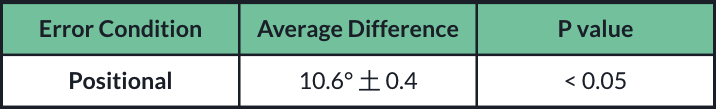

Design Input 1 – Verification

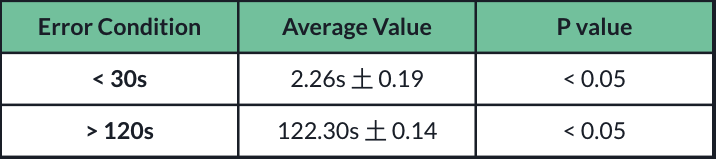

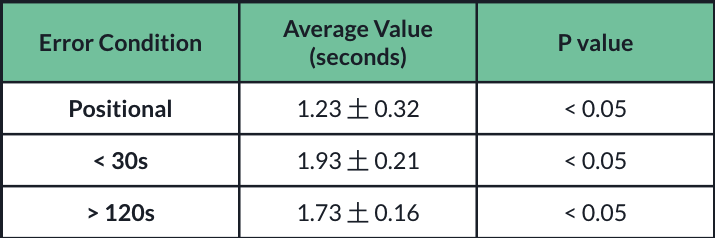

- Device was positioned so error conditions in position and time occur

- Similar process to that of Design Input 3

- Device positioned just outside of target angle so errors would occur

- Difference between this angle and the target angle recorded

- No resolution for this spec

- Device is still able to accurately measure errors within the range of 10 to 11 degrees

- One tailed one sample t-test used

- When time error occurred also recorded

- < 30s and > 120s

- Device reported errors within the expected time frame

- One tailed t-test compared with 30s and 120s respectively

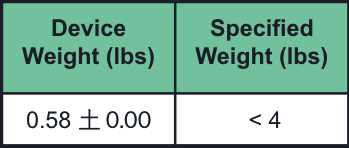

Design Input 2 – Verification

- Device weight was 0.58 lbs

- Weighed 3 times and averaged

- One tailed one sample t-test done

- Compared to max weight of 4 lbs

- P < 0.05

- Device weight significantly different than 4lbs

- Passes verification

Design Input 3 – Verification

- Simulated Head used to record different angles

- 100 data points recorded

- 0, 90, 180° on x-axis

- -50, 85, 245° on y-axis

- 65, 145, 225° on z-axis

- Difference between target angle and recorded angle taken

- Angles chosen 20 degrees past range of Epley Maneuver and middle

- Wilcoxon test used

- Data not normally distributed

- Compared to see if difference was less than 1

- All angles pass with p < 0.05

- Device is able to measure target angles within 1 degree

Average difference from target angle with error bars and target values (p < 0.05)

Design Input 4 – Verification

- Device positioned or timed into different error conditions

- Utilizing simulated head similar to design input 3

- Time taken for feedback to be administered recorded (n = 10)

- Values averaged

- One tailed one sample t-test performed

- Compared to hypothetical mean of 3 seconds

- Less than 1/10th the time per step in the maneuver

- Passes verification for design input 4

Design Input 6 – Verification

- Baud rate of 9600 confirmed to be used in Arduino

- Corresponds to 960 bytes/s

- 7.68 kbps

- Fails verification for design input 6

- Due to the nature of how Arduino transmits data this was unable to be reached

- Using a different microcontroller chosen in the future would fix this

Design Input 7 – Verification

- Device was powered on either for five hours or until battery died

- Power lasted for the full five hour period

- Device passes verification for design input 7

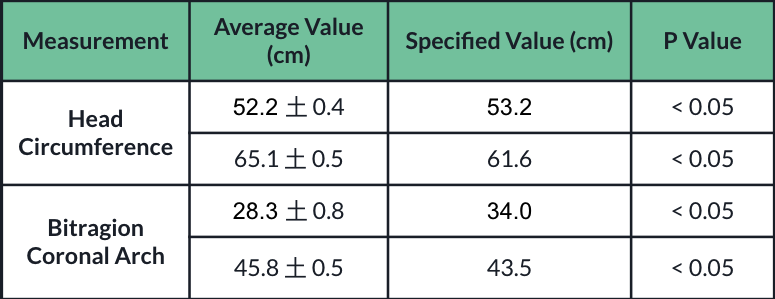

Design Input 8 – Verification

- Minimum and maximum adjustable values measured (n = 3)

- Done for head circumference and bitragion coronal arch

- One tailed one sample t-test performed for minimum and maximum values

- Device passes verification for design input 8

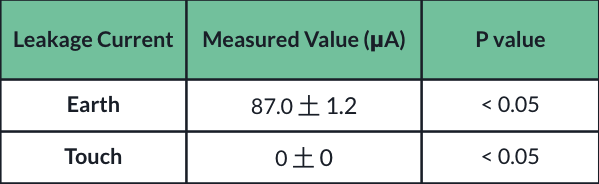

Design Input 10 – Verification

- Leakage current testing done in accordance with IEC 60601

- Minimum earth leakage current: 5 mA

- Minimum touch current: 0.1 mA

- 5 Measurements taken each

- One tailed one sample t-test performed

Body model used to test touch current