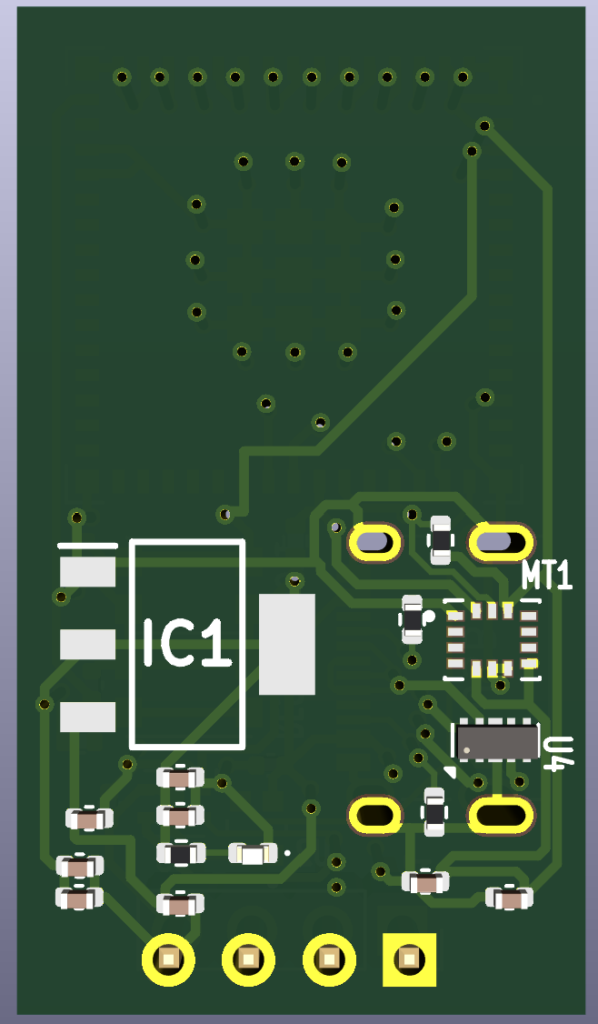

Over the past month, our team has been exploring different ways to power our embedded module platform using a lithium-ion battery. Since portability is an important goal for the ComIoT system, finding a reliable and efficient battery solution is a key part of our design process.

During our research, we identified an important requirement: a standard lithium-ion cell outputs around 3.7V, which is higher than what our board safely supports. Our hardware operates within a range of 2.2V to 3.6V, meaning we need a voltage regulator to step the lithium-ion battery down to a stable output.

We’ve been evaluating different regulators and power management options to ensure the board receives clean, consistent power without introducing noise or instability. This includes looking at low-dropout regulators (LDOs), buck converters, and integrated power management modules.

Finding the right solution will help us move closer to a fully portable, battery-powered version of the platform. More updates coming soon as we test and finalize our power design choices!