Introduction

In order to achieve the results required, we need to successfully launch and recover the balloon without damaging the payload attached to it, while also meeting the project specifications. As a result, we need to use the correct balloon size, gas, parachute size as well as materials to make sure the payload and balloon will be able to endure the conditions of the flight. For this to happen, research was conducted to see what materials and setup would be most conducive to our anticipated results.

Theory

The first thing that needs to be done is choosing the balloon for the launch. The balloon will create limitations on the weight and achievable altitude of our project. Then based on the balloon specifications the amount of lift needed which can then determine the amount of helium needed. Each cubic foot of helium can lift 28 grams. Each pound of free lift would mean 300 feet per minute of ascent rate. Increasing the free lift and therefore the ascent rate decreases the flight time of the balloon, making it less likely for your electronics to run out of battery power. However, too much helium in the balloon could make the bursting height too low.

Weather balloons are characterized not by their size but rather by their weight. By using a 600g balloon, the balloon is easier to handle while on the ground and therefore is recommended for amateur balloon launchers as the inflation and launch processes have less complications with a mid-size balloon as you can often get balloons up to 1200g as well.

|

Specification |

Details |

|

Weight |

600 g |

|

Material |

Natural Latex |

|

Inflation Gas |

Helium |

|

Payload |

1-2 lbs |

|

Rate of Ascent |

350m/min |

|

Burst Diameter |

19.8ft |

|

Burst Altitude |

75,000 – 90,000ft |

|

Neck Diameter |

3.0 cm |

|

Neck Length |

12.0 cm |

Implementation

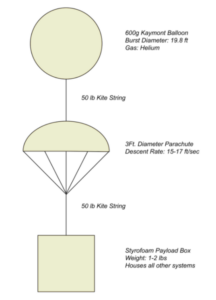

Balloon System Schematic

As this is a new experience for all group members, we will be using a 600g weather balloon from Kaymont Consolidated, and will connect the balloon to the parachute using 50lb kite string. The parachute will then be connected to the payload (styrofoam box) through a 4-point harness in conjunction with a 50lb kite string. The harness will prevent tangling of the string and the carabiner/loop that will secure all the strings to a singular point. In this scenario, 50lb kite string is being used as it is at the limit for tensile strength for not needing special FAA clearance. If we were to use a higher strength string, we would need to get special approval.