Build Progress

Sanding & Prep (9/9/22)

The edges of the boat were sanded down for a more streamlined shape and less abrasive finish.

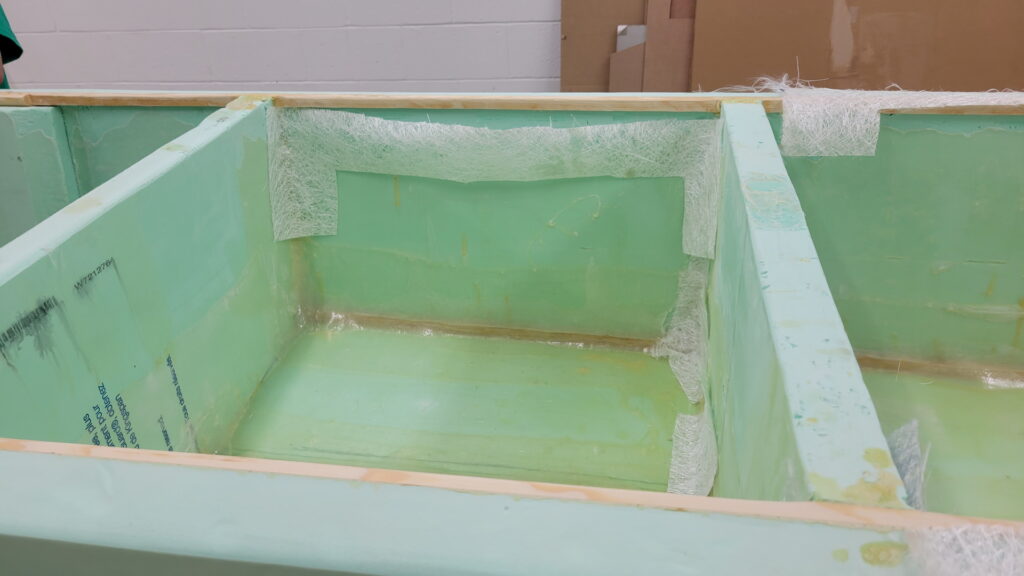

Fiberglassing Day 1 (9/29/22)

The first round of fiberglassing involved laying down patches over the sections of the hull that were still bare, then setting it with epoxy.

Fiberglassing Day 2 (10/6/22)

The second round of fiberglassing involved laying down a stronger woven fiberglass over the bulkheads for added strength and waterproofing.

3D Scale Model of Hull Created (10/7/22)

A scale model of the hull was 3D printed for easier visualization of component placement. The 1:29 scale model measures 6 inches in length and has similar flotation characteristics to the full-size hull.

Fiberglassing Day 3 (10/27/22)

The third and final round of fiberglassing involved laying down more of the woven fiberglass, this time over the gunwale of the boat.

First Water Test (10/31/22)

This first water test marked an important milestone in the development process. In addition to verifying the integrity of the hull, we were also able to measure the water line and perform the competition’s test for lateral stability.

Winter Break (12/20/22 – 1/22/23)

Winter break saw the team make significant progress in the design and fabrication process.

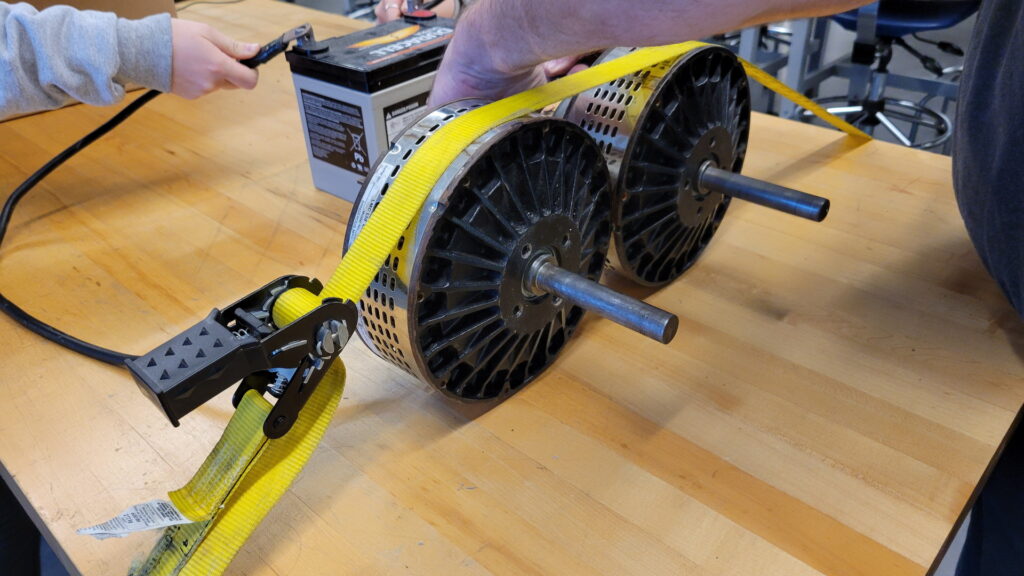

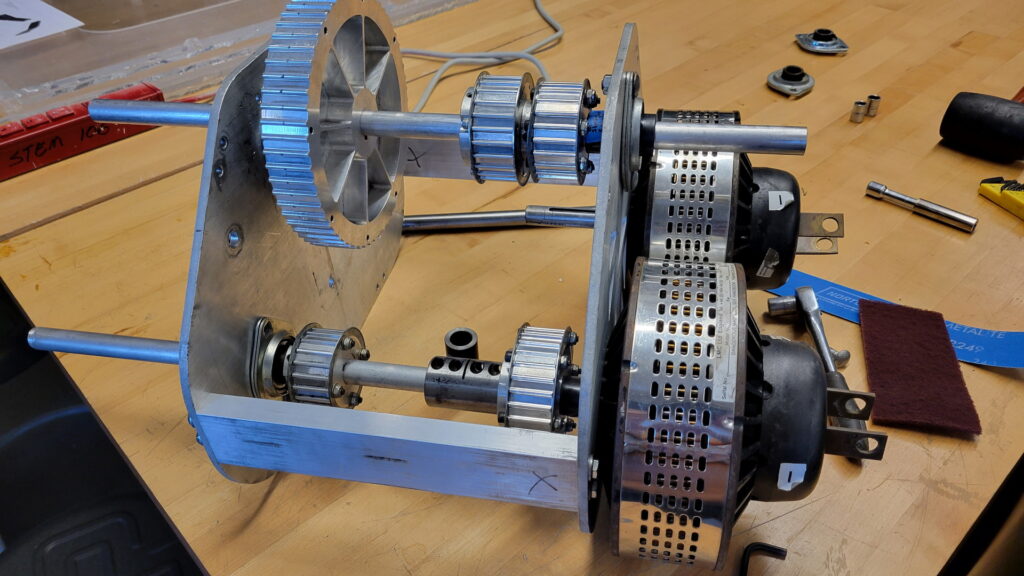

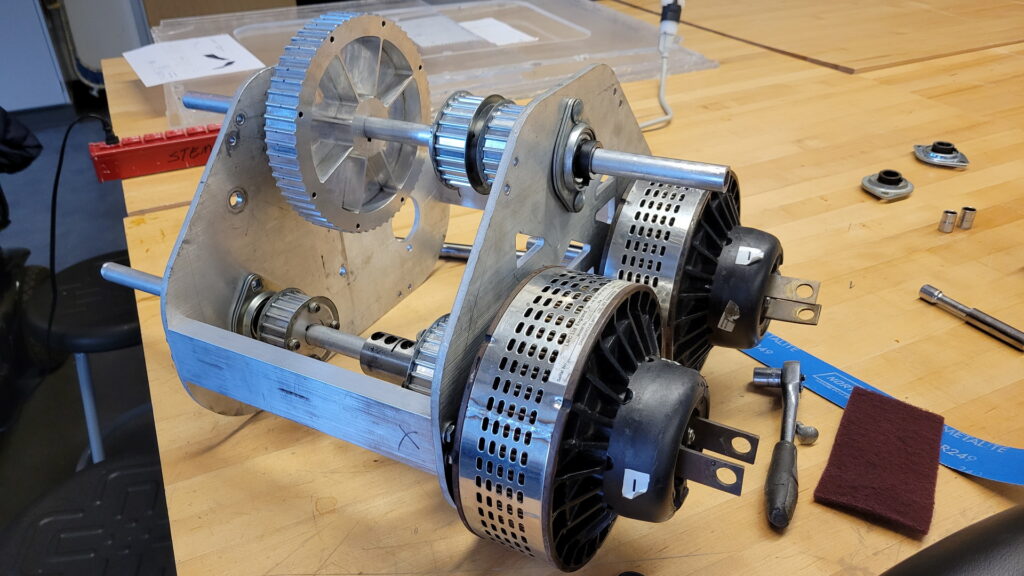

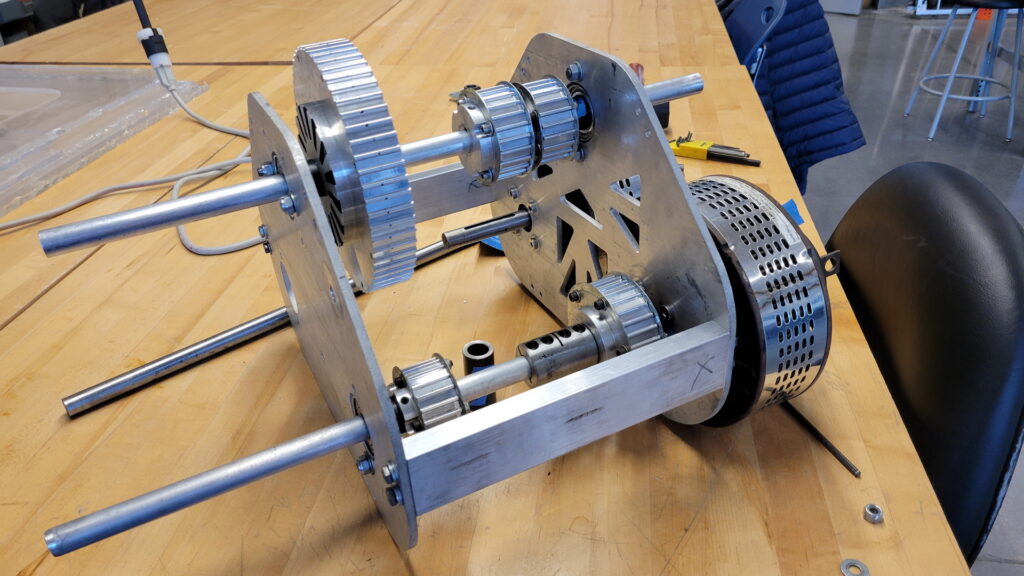

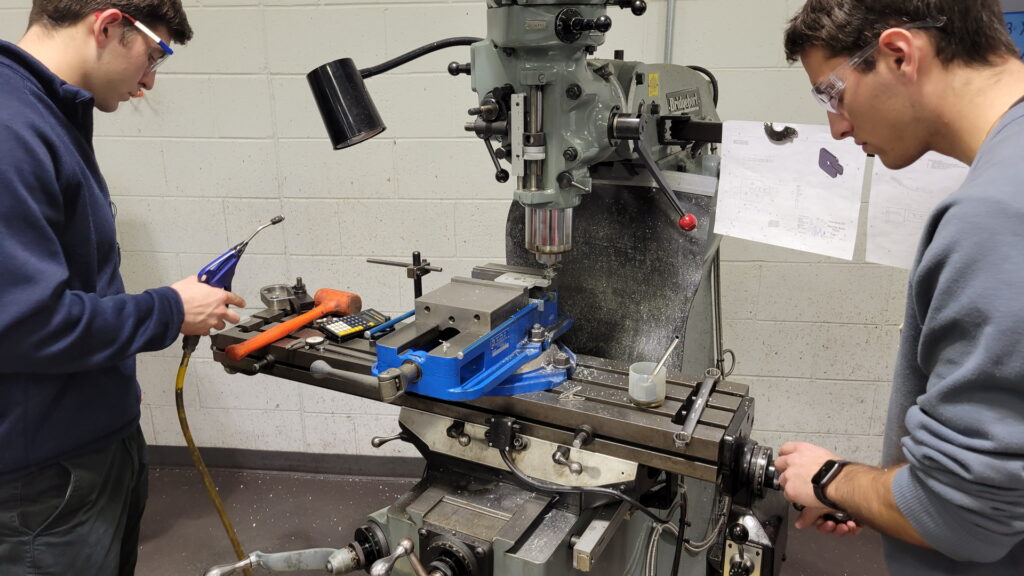

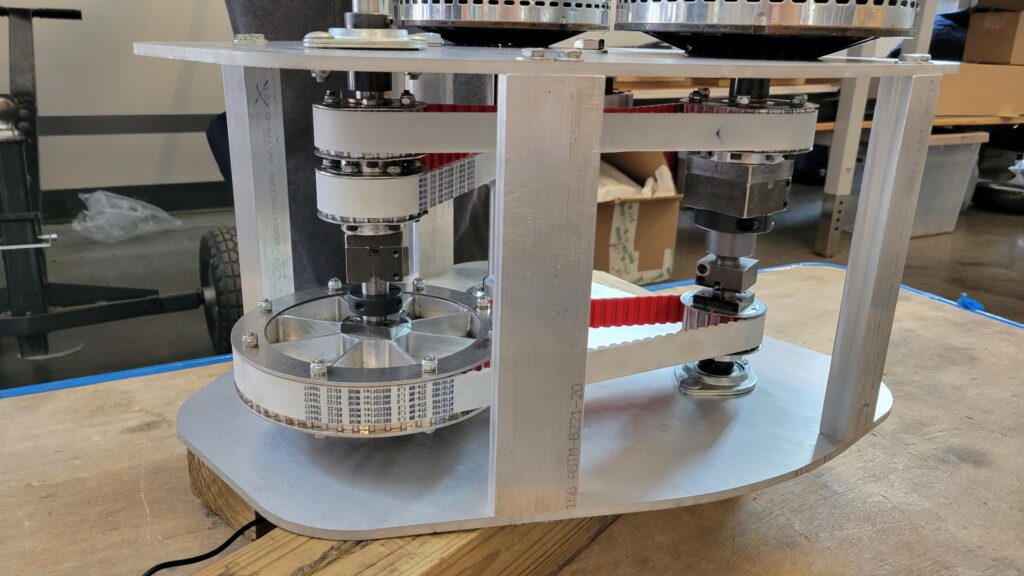

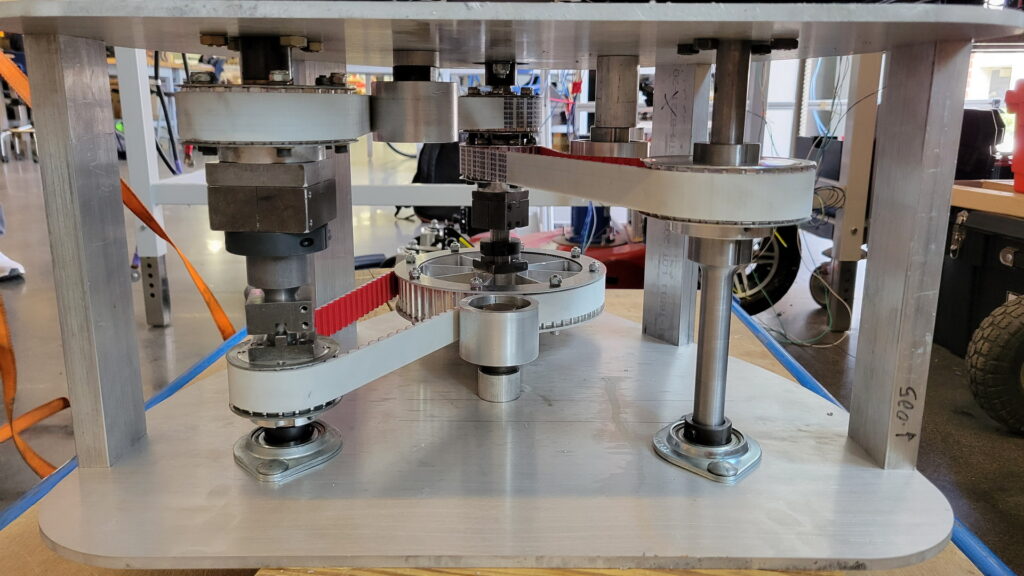

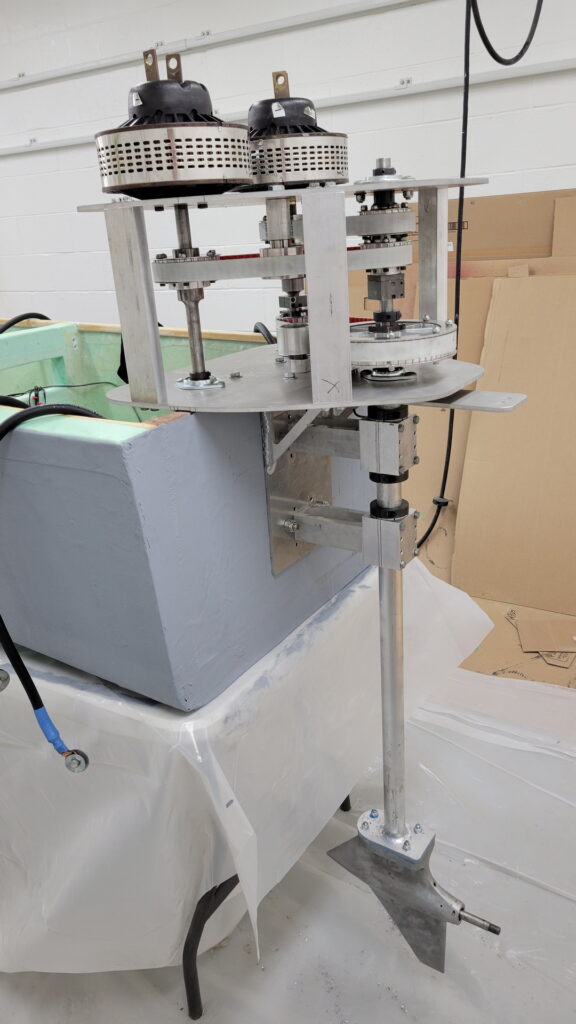

The drivetrain underwent a complete redesign since being presented at SP I, and manufacturing is now under way. The key components that have already been manufactured were test-fit on previous versions of the frame to ensure the validity of their geometry, which was a successful endeavor. The two motors were also tested and determined to be operational, and will undergo further testing to verify their rated power output.

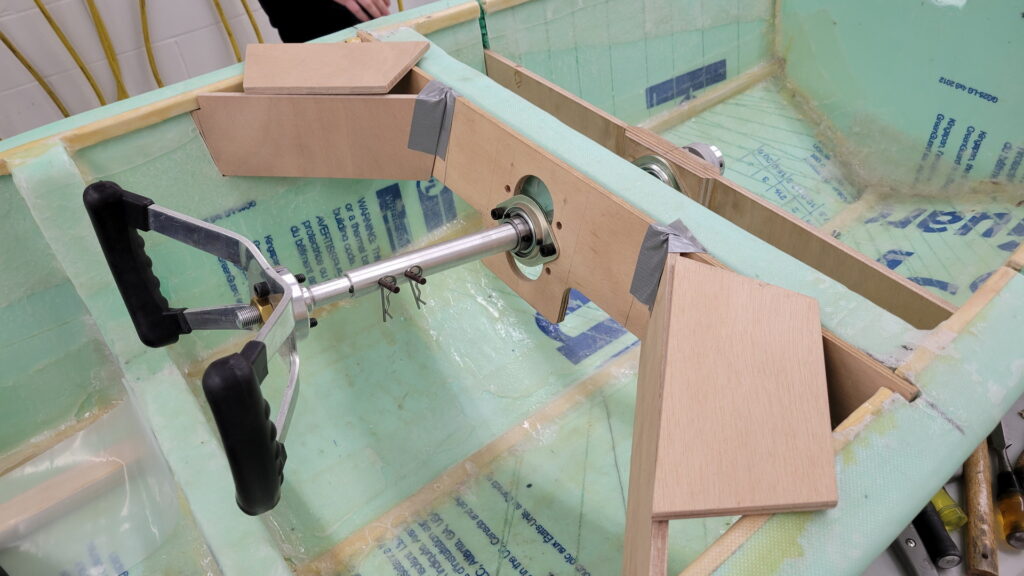

On the steering front, almost the entire steering assembly has been fabricated, assembled, and installed in the boat, the only exception being the steering cable and its accompanying pulleys. Additionally, the wheel-mounted throttle assembly was redesigned with new geometry and materials, and has since been installed on the butterfly steering wheel.

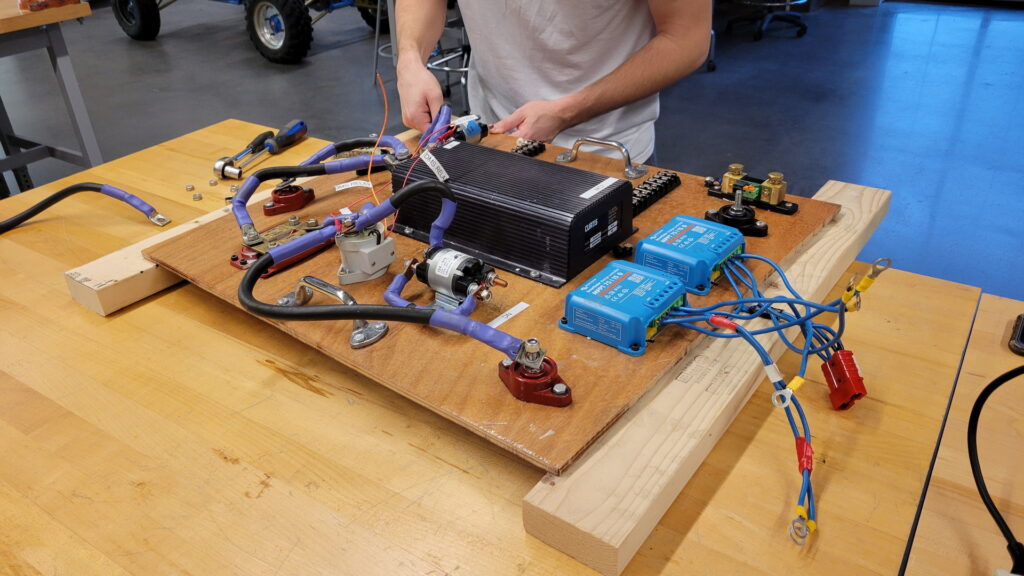

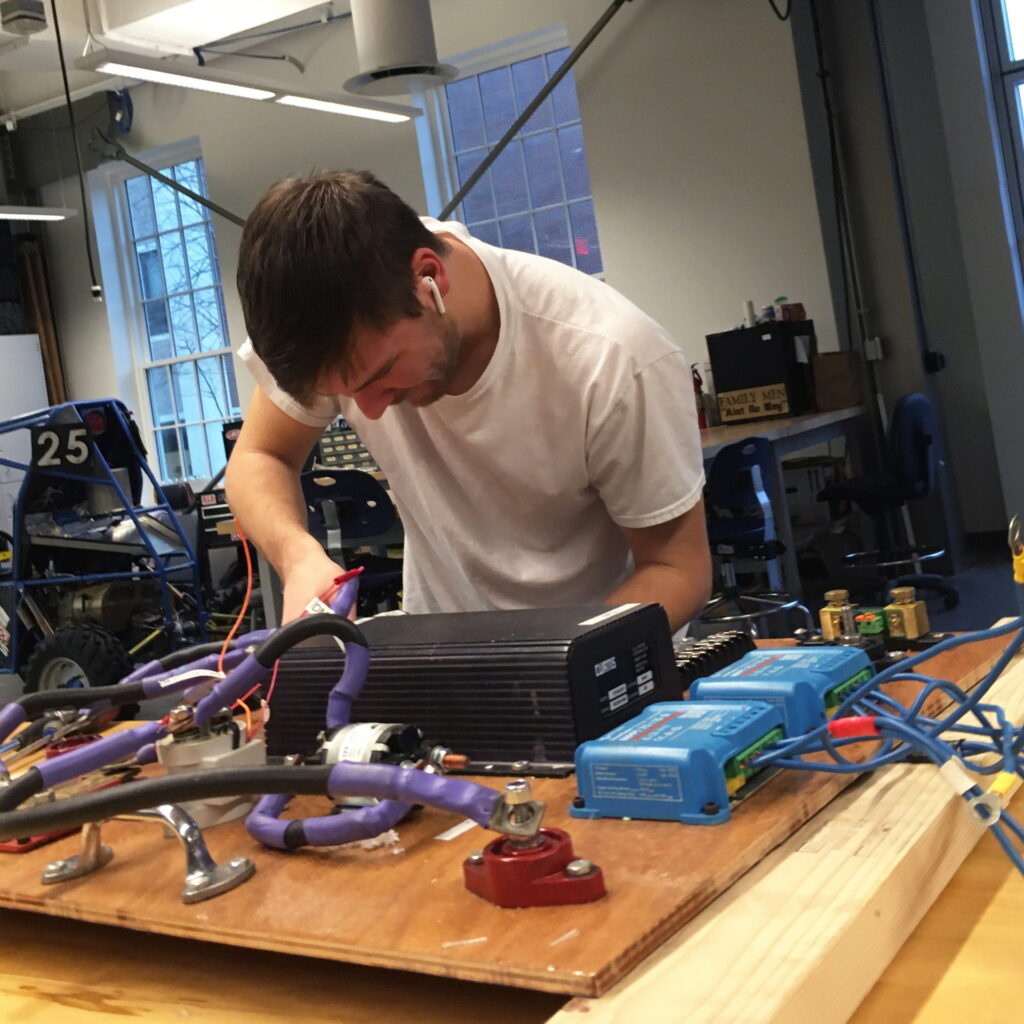

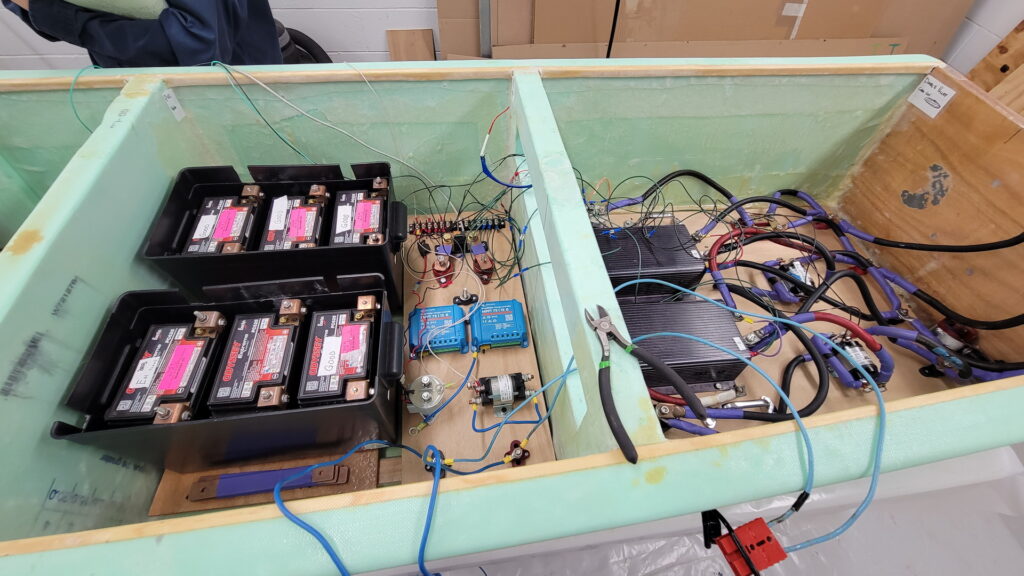

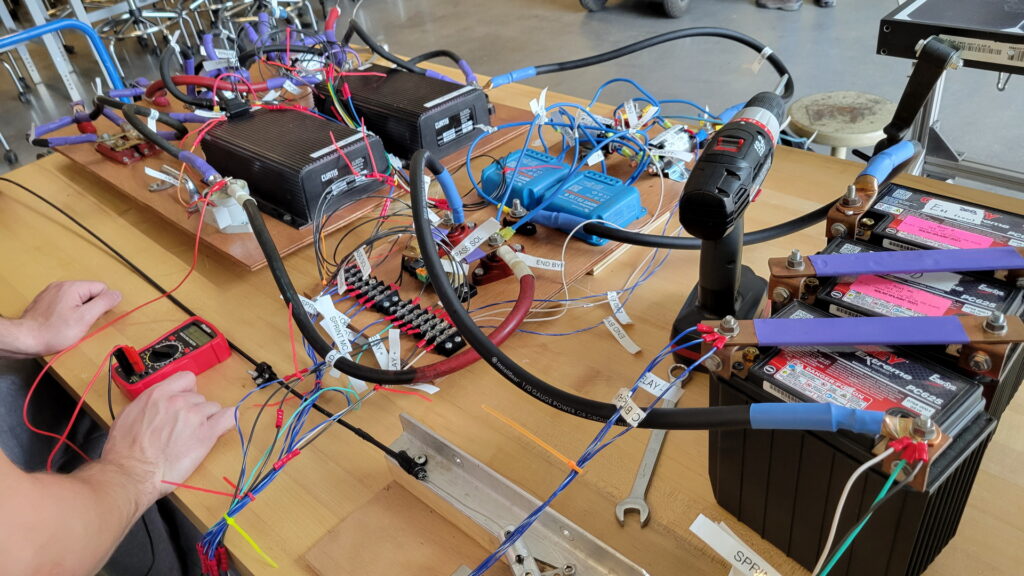

Over at electrical, all components currently in our possession have been laid out and attached to the electrical board, which itself has been fitted to the hull for preliminary sizing checks. All necessary gauges and controls have also been added to the dashboard and wired up to the main circuit.

Finally, the hull underwent significant refinishing, and the necessary modifications to accommodate each subsystem were added. Such additions include the dashboard mounting points, drainage tubes between the bulkheads, a tow hook at the bow, and the slot for the unused lower unit that will be swapped between events.

Manufacturing, Testing, & Systems Integration (1/23/23 – 3/31/23)

Since winter break, the team has been hard at work readying the boat for competition, having nearly completed the watercraft in full by the end of March.

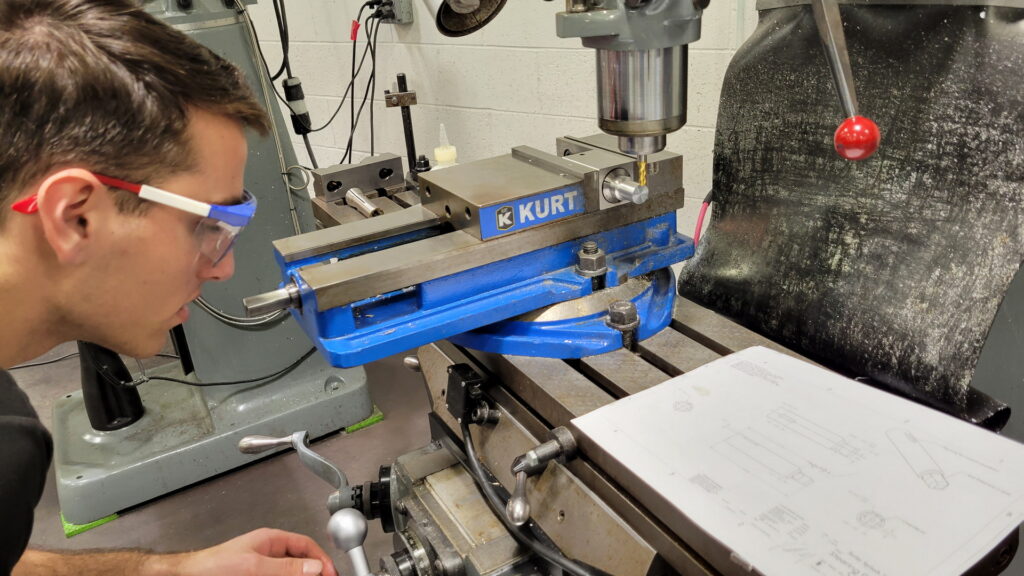

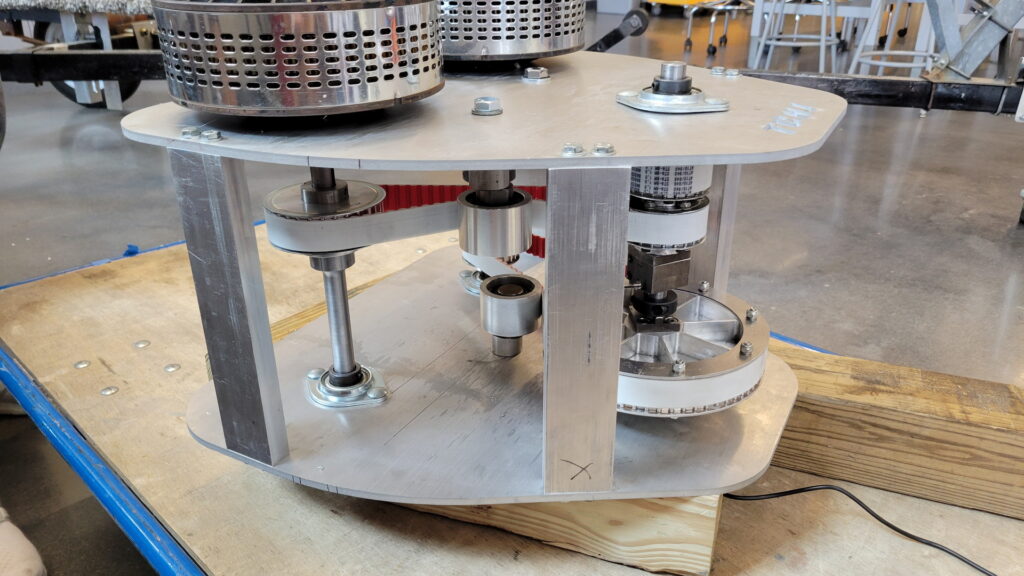

There was a large push in manufacturing components for the drivetrain, with the entire powerhead and the majority of the powerhouse being completed as of this milestone. The drivetrain was fitted to the hull to ensure proper fitment, which was achieved, and now all that remains is the creation of the support brackets before final assembly will take place.

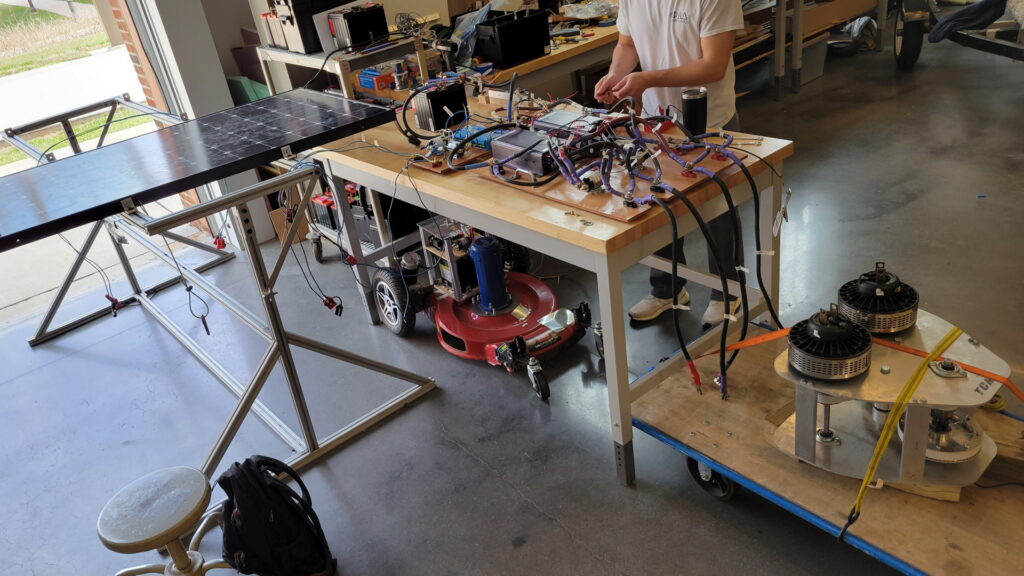

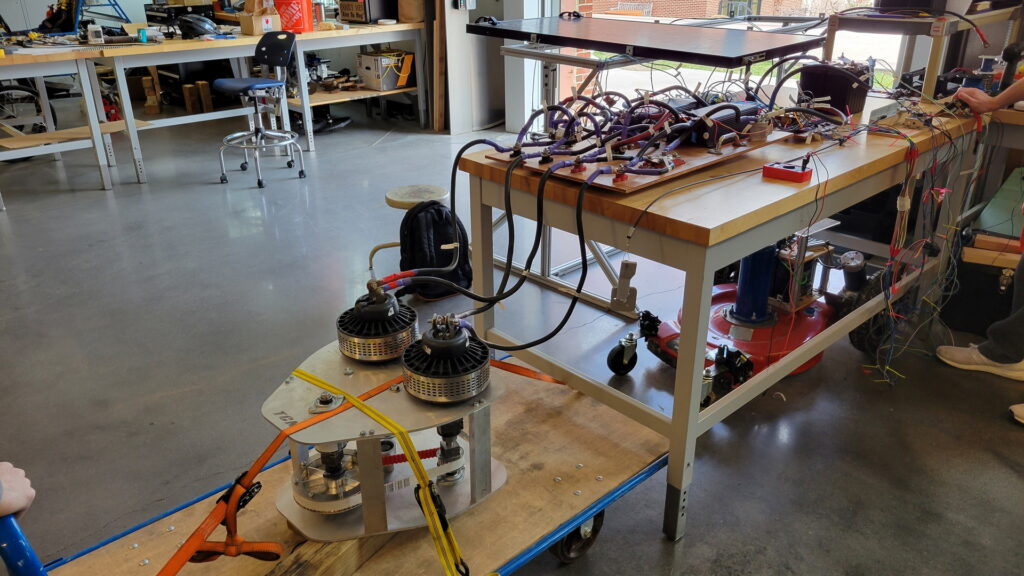

As for the electrical system, the motors were tested on the circuit with no load, as well as with as with the transmission in place to verify both the motors’ functionality and the validity of the drivetrain concept. In addition, these tests were also performed using exclusively solar power (as opposed to battery power) to verify that the solar panels work. All in all, it was determined that the circuit, its solar-powered capabilities, the motors, and the drivetrain all function as desired.

Lastly, the steering system, which was completed over winter break, was reinstalled into the hull, which itself received a keel and multiple coats of sealant to prepare the boat for its first powered water test. All that is left for these two subsystems is performing the final finishing and painting on the hull, and attaching the steering cables to the steering knuckle on the powerhouse.

Finishing Touches (4/1/23 – 4/11/23)

The custom parts for both powerhouses were fabricated and assembled. This allowed for attachment of the steering cables to the I-hooks on the steering knuckle. Following that, the L-brackets supporting the powerhead were created, then attached to the hull. Finally, the dashboard components were installed, finishing off the cockpit. The boat was now ready to hit the water.

First Powered Water Test (4/12/23)

The first powered water test provided the team with a great deal of valuable information. On the positive end, the boat floated without any issues and was able to drive under its own power. It also met all the necessary safety standards set in place by the competition. With that in mind, top speed and battery life were below the team’s original targets, and the steering had a tendency to pull to the right due to the aggressive propeller in use.

To remedy this, a number of solutions were implemented in each affected subsystem. For the drivetrain, all sources of unnecessary friction were identified and removed. This was done by modifying the clearance and clamping mechanism of the shift dogs, as well as altering the alignment of the lower driveshaft in the powerhouses. On the electrical front, the batteries were serviced by cycling them through multiple charges and topping them off with fresh distilled water. Finally, the steering system received stronger braided steel cables to replace the nylon ones, and springs were added to the steering knuckle to aid in self-centering.

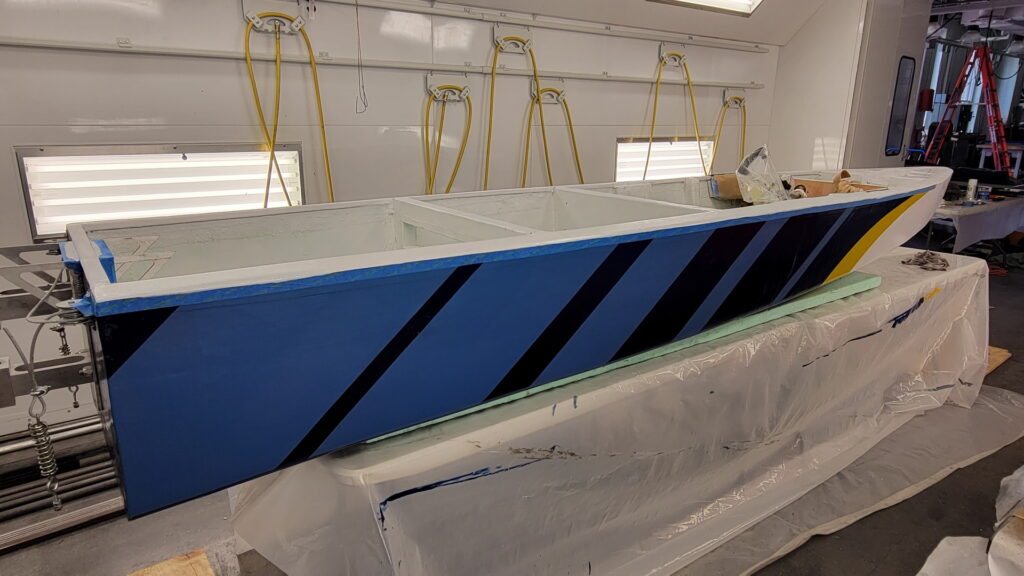

Painting (5/15/23 – 5/19/23)

After resolving the issues faced in testing, it was time to paint. The first day involved laying down a fairing compound, which smoothed out the surface of the boat to better prepare it for the paint. Since nothing else could be done until that was dry, It was not until the next day that painting began.

Once the fairing compound was fully cured, the first coats of the navy blue and white paint were laid down, then a second coat of each was applied the following day. After the navy and white were deemed opaque enough the next day, the first coat of yellow was laid down and the area for the light blue stripes was masked off while it dried. The final day of painting saw the application of a second coat of yellow, as well as the only coat of light blue for the stripes. Once those were dry, the interior and the gunwale of the boat were painted white, the former using spray paint and the latter using rollers.

2023 Solar Splash Competition (6/6/23 – 6/10/23)

After a year of hard work, the team finally got to put the fruit of their labor to the test at competition. The five-day event saw 9 teams from around the globe compete with their boats in two qualifying events, a slalom, three 300-meter sprint races, and two 2-hour endurance races. Teams were also judged and awarded points for their off-water efforts such as their technical report, video presentation, and workmanship.

We are happy to announce that we placed fifth overall at the competition, winning the Drive Train Design Award, Innovation Award, Second Place Video Presentation, Third Place Technical Report, and Third Place 300 Meter Sprint Event in the process.