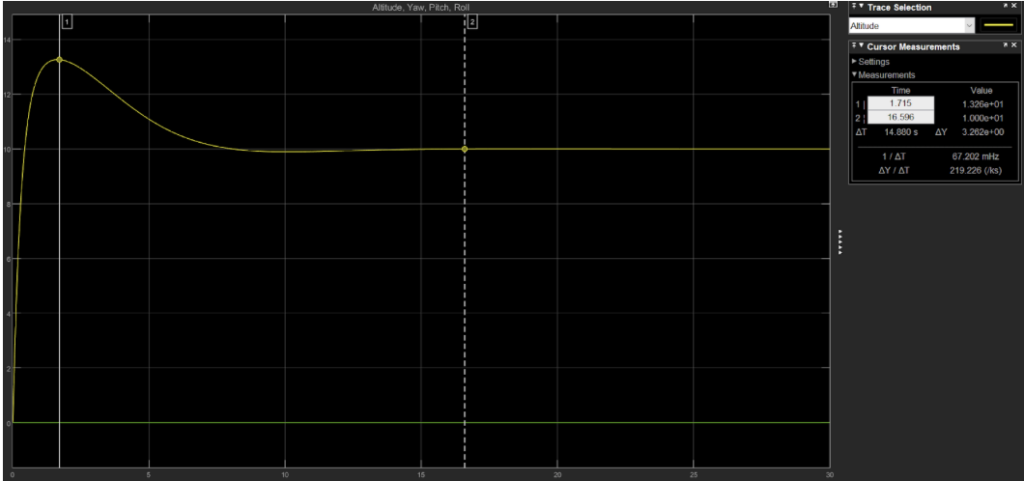

At this point in the semester we have completed the full construction of our gimbal rig. We are entering the testing phase for our drone very shortly. We will be testing both on and off the gimbal rig in the coming weeks. Things we will be testing for include battery life during flight, stabilization, and autonomous movement. We will also be implementing our camera component once stabilization testing is complete to start taking and storing photographs with the drone.

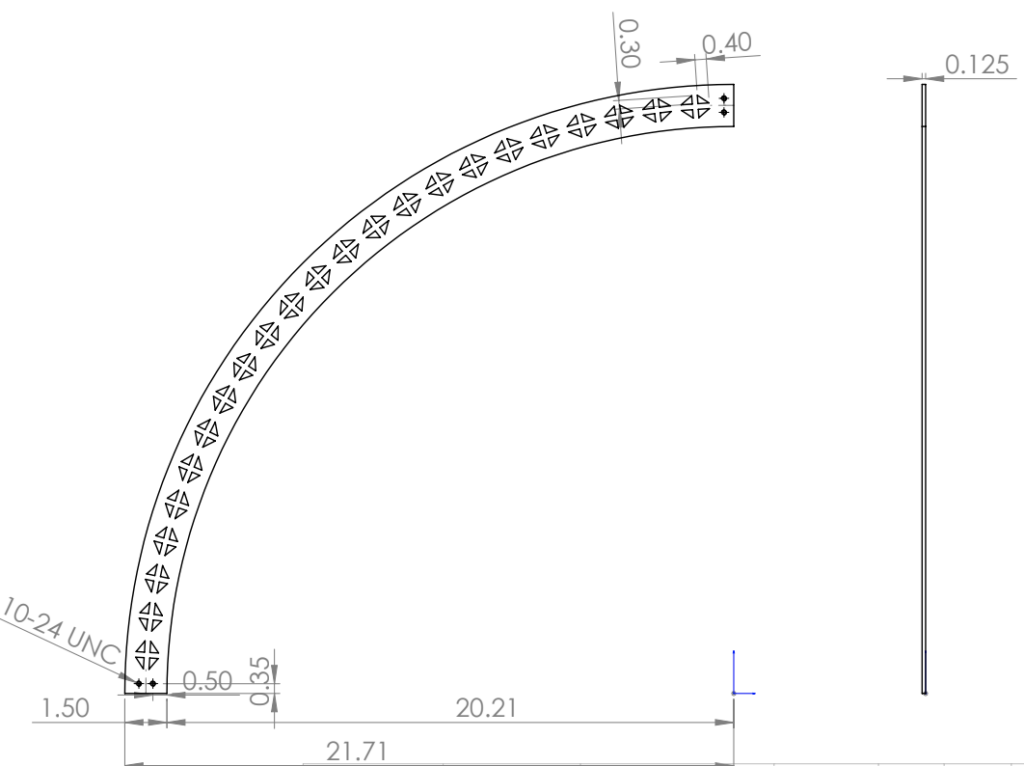

Here, we have the gimbal rig full assembled. All there is left to do is to attached the drone and begin testing! This gimbal rig is located on the 2nd floor of the STEM building, inside the drone lab.

Here, we have a demonstration by William showing the gimbal rig rotating with ease. This will allow students to test for degrees of freedom whenever we are incorporating tuning values.