The CVT lower pulley on the left and the upper pulley on the right have been cleaned and prepared for bench testing. Expect updates on bench testing soon after the gearbox is completed.

Monthly Archives: January 2016

Updated Rear Suspension Geometry and Model

Shown above is the most updated 2D Sketch of the Rear Suspension Geometry which satisfies our needs in terms of bench-marking and various design parameters

Shown above is the most updated rear suspension 3D model. The geometry and modeling has been finalized in an attempt to allow our driveshaft provider, Neapco, with adequate dimensions to fit us with a shaft that will meet our needs. Moving forward the carrier and the hub models will be finalized and will be machined in-house in the weeks to come.

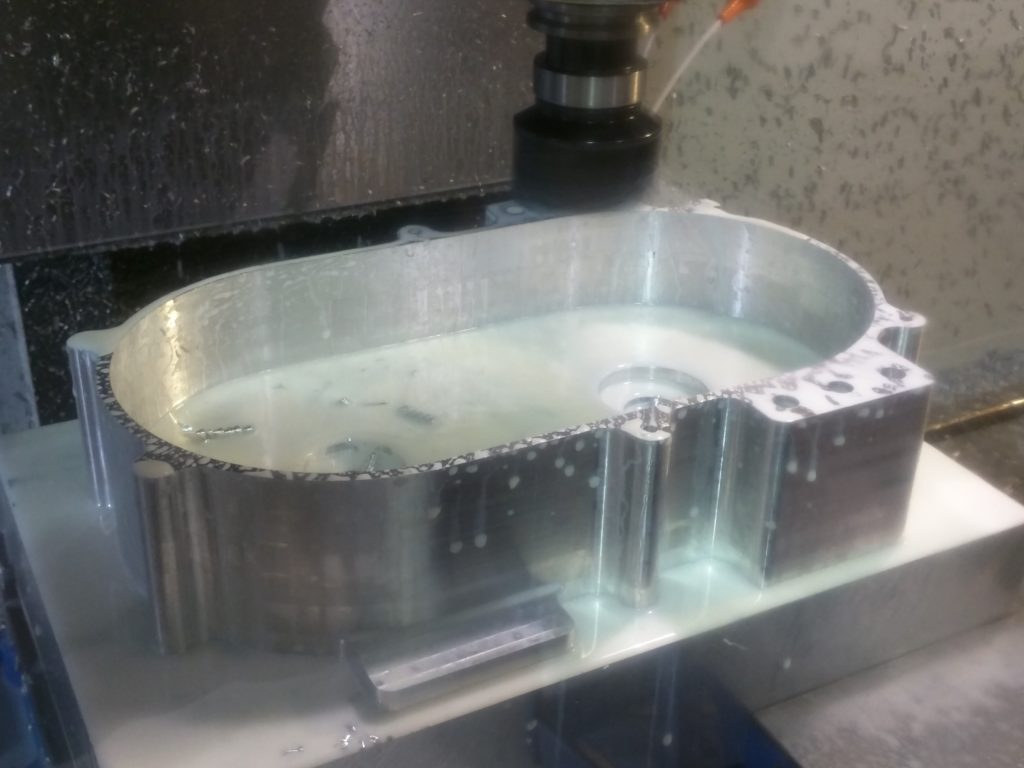

Gearbox Machining: Day 3

Hello Everyone,

The progress on the gearbox today was less dramatic, but work on the one side of the gearbox was completed. The whole assembly has now been flipped and machining can now commence on the other half of the gearbox.

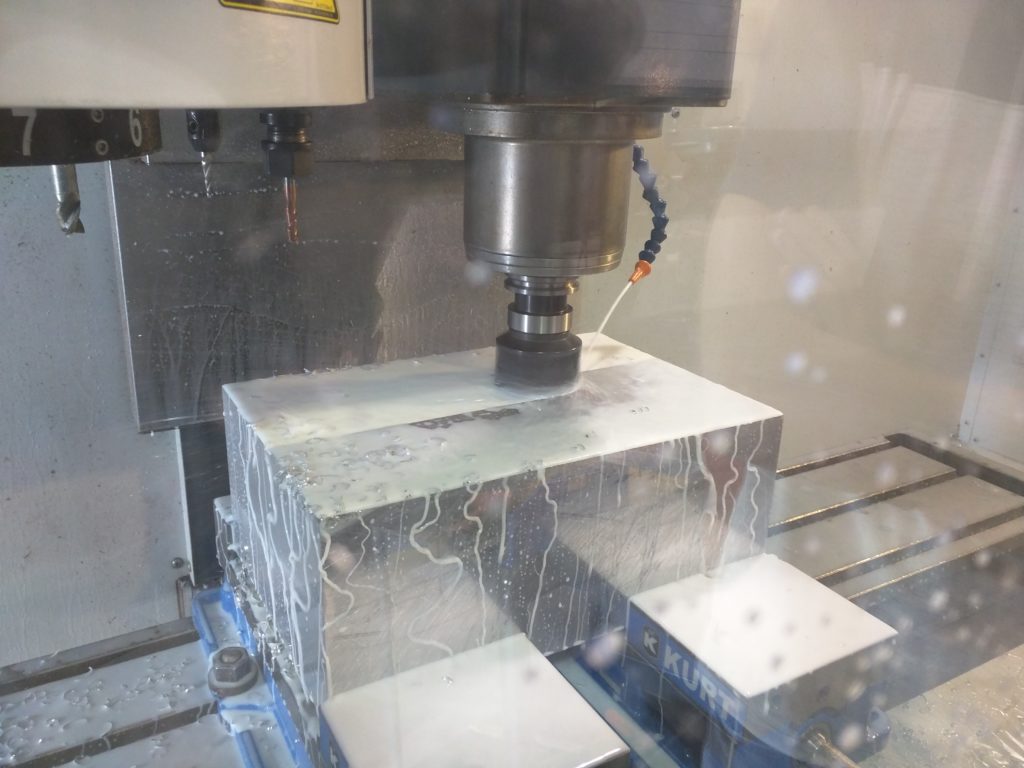

Cleaning up the edge of the gearbox base with a slab mill.

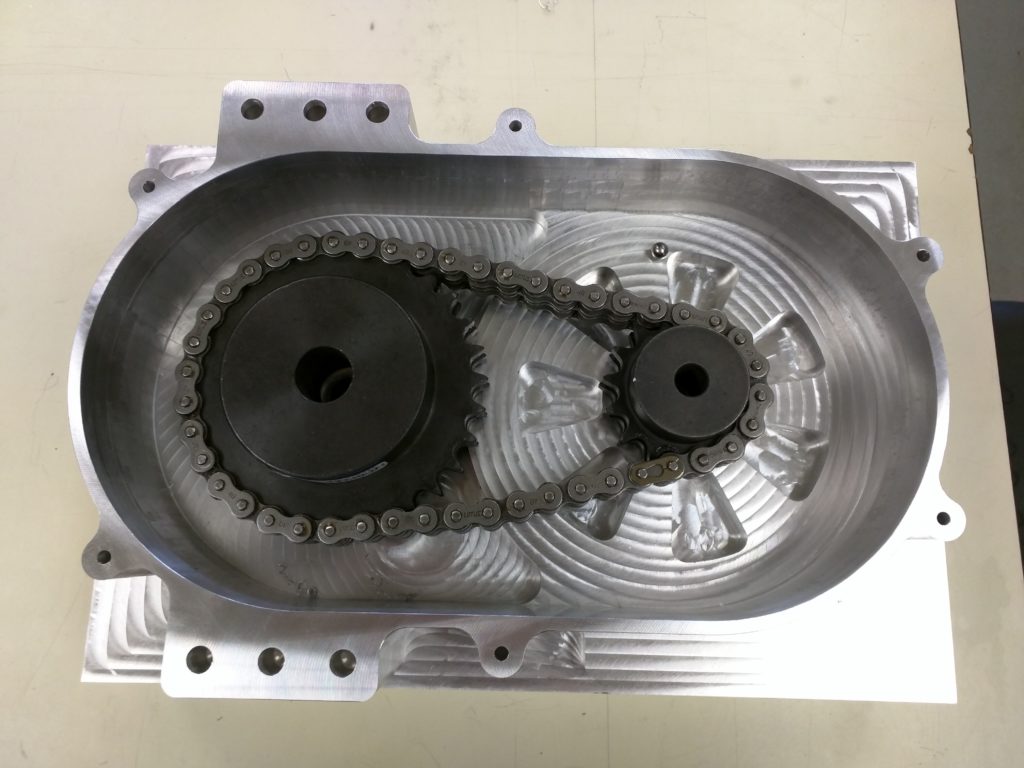

One side of the gearbox now complete with bearing bores and mounting holes. The mounting holes were tapped by hand after removing the gearbox from the CNC.

Here’s a little sneak preview of the sprockets that will sit in this half of the gearbox. Wonder what will go in the other side ….

The finished half of the gearbox bolted down to another plate and ready for machining on the other side. More exciting work to come.

-Michael S.

Gearbox Machining: Day 2

Hi All,

There’s still a lot of machining to be done on the gearbox, but our second day on the CNC brought a lot of progress. We cut out almost all of the features on the one side of the assembly.

Cutting out the inside of the gearbox. Very milky.

This video shows the radius cutting on the bearing boss. Look at smoothness of the final radius.

The final results of the work on Day 2. Once we cut some bearing bores and drill some holes, it will be time to flip to the other side of the aluminum block. Look for more progress tomorrow.

-Michael

Gearbox Machining: Day 1

Hello All,

I’m very excited to announce that the machining of our new gearbox began today. During the day today, we completed the first three steps in the machining of the gearbox.

The first step was to square of the face of the aluminum blank as shown in the first image.

The second step involved drilling the two center wholes through the gearbox using a huge drill bit.

Finally the outside edges were cut using an end mill to give us a blank resembling a gearbox by the end of the day.

If all goes well, we’ll be machining out the inside of the casing tomorrow.

-Michael

Manufacturing Progress and Sponsor Highlight: Rancocas Metals

Hi Everyone,

I wanted to highlight one of key sponsors, Rancocas Metals, and offer at sneak peak at some of the work we’ll be doing to turn their aluminum into a gearbox.

We greatly appreciated Rancocas continuing to support TCNJ Baja through discounted aluminum products. Look at that huge 6x15x15 inch block. On Wednesday, we started cutting the block to size on the bandsaw, and the CNC cutting should begin this coming week. Look for more updates on that progress.

-Michael