Update 1: General Project Approach

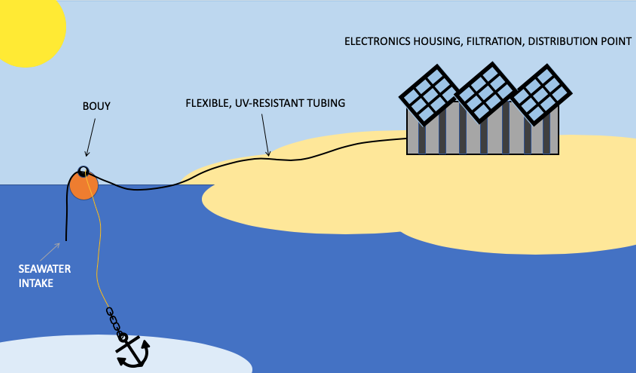

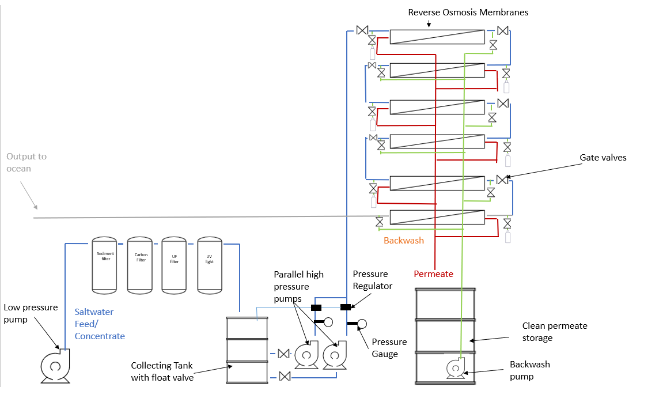

The team has accomplished a general picture of what their full-scale model will incorporate. The team has eliminated thermal methods of desalination due to energy requirements and has begun evaluating a Reverse Osmosis Design. Below is a mock overview of how they envision their full solution to appear while its in operation. Further, the team has conducted preliminary analysis after research and has developed a P&ID Diagram for their system. The team has opted for a low-pressure pre-treatment phase before undergoing a high-pressure reverse osmosis phase. Further, the team has incorporated a backwash system to be used when pre-filters are exchanged correcting any fouling of the RO Membranes.

Update 2: Full-Scale Modeling & Electrical Diagram

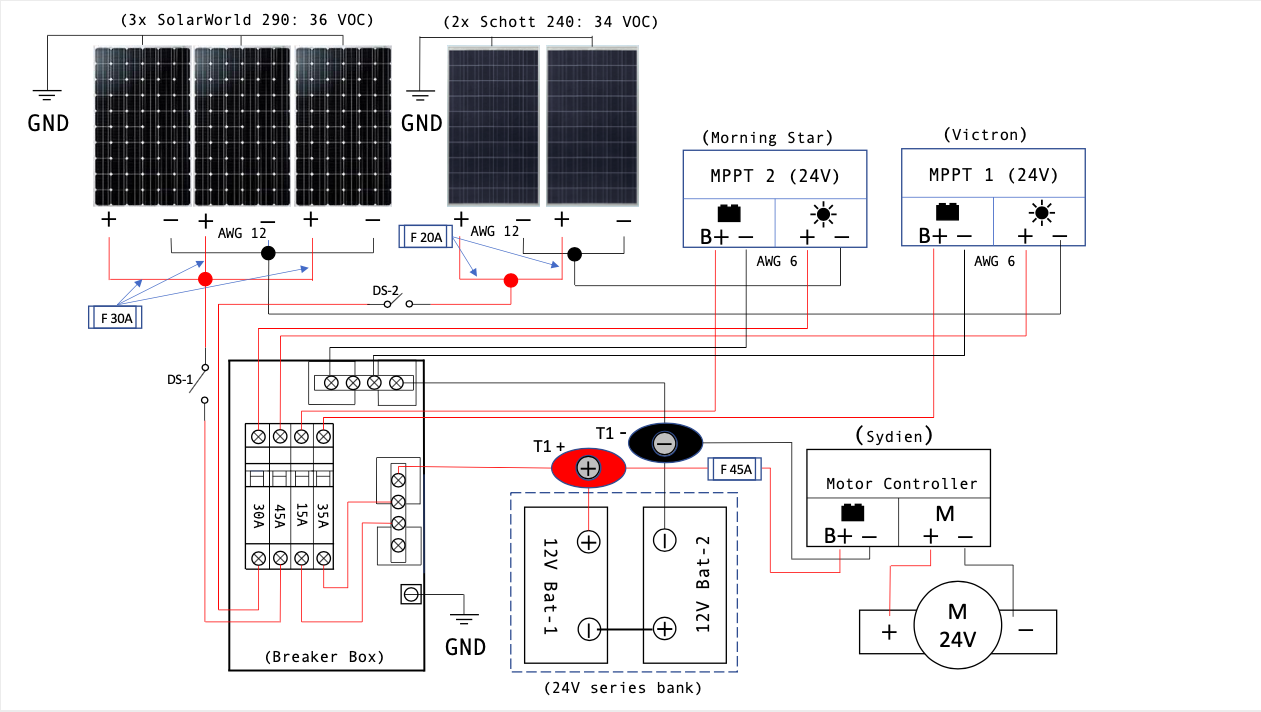

The team has opted to go for a shipping container housing for ease of transport and weather resistance. A full SolidWorks model has been developed for display below. This system houses all the necessary components when shipping, including storage for all 1200 gallons of freshwater. When in operational mode, doors unlatch and an array of 10 panels on industrial slides come out. An additional 10 panels are then available with framing to be attached and assembled to the top of the crate to maximize space usage and keep the panels above ground. Additionally, 200+ ft of tubing are available onboard as well as the anchor and buoy assembly to retrieve water from the source. A mock diagram of the shipping container displaying TCNJ materials has also been made available to maximize the potential of the crate. Further, an electrical diagram has been developed to provide a basis for the analysis of the DC to AC array.

Update 3: Senior Project I, Full Project Update

The fall semester is coming to an end and the team has a full grasp on where the project is heading. Senior Project Design Presentations went very well for the group, with multiple persons feedback being positive and very interested in the project. Further, juniors watching the presentation have also mentioned their interest in the project for next year. The team has made minor additions to the Full-Scale assembly, but unfortunately, this design will not be funded for its full price being over $35,000 as it stands currently. Instead, the full-scale model will have full computer modeling built to test its functionality and safety. To further test the project, a proof of concept model was also designed and presented. This model is barebones solar desalination, capable of only treating salted water and not seawater. This model will be pitched for funding from the dean shortly. Not shown at the presentation due to time is another proof of concept model, slightly more expensive but including pretreatment, making it seawater capable. This will also be pitched to the dean for funding. The team will provide updates shortly regarding funding.

Update 4: Funding Secured

The fall semester has concluded and the team’s budget has been approved by the Engineering Department! We are very grateful to have received some funding for P.O.C. 1 and will continue to seek outside donations (see Our Supporters) to realize the project. The team will begin ordering parts and constructing P.O.C. 1 over winter break.

Update 5: Build Progress

Since our last update, the team has put forth a tremendous effort to source donations from our growing list of wonderful sponsors. With their overwhelming support, many parts have been received at a discounted rate or free of charge. At this time, most major components for P.O.C.1 have either arrived or are being processed through the campus receiving office.

The mobile wooden base construction for P.O.C 1 has been built, as well as a vertical, tiered “electrical box” currently being fitted with all electrical equipment, less the solar pannels. Nearly all major and minor electrical components have been tested independently using battery power and lengths of recycled wiring to evaluate their performance. This includes the soft-starting motor controller and electric motor pairing, which worked flawlessly, and all switches and breakers. Minor design changes have been made to the electrical system to include more fuse and switch redundancies for safety and component isolation purposes. Should the budget allow it, an amp-hour / system voltage monitor will be purchased so that important system metrics can be seen in real-time. Only a few minor electrical components are awaiting delivery to finalize the electrical system.

As of now, the team has the reverse osmosis membrane and pressure vessel, as well as both the high and low-pressure pumps. Due to the generosity of our supporters, the team has sourced high-pressure tubing, pressure regulators, and the necessary fittings for proper installation. Once these components arrive, the team will begin assembly and testing.

Testing will begin in phases to be sure each subsystem runs safely and as expected before performing a full system trial. For this full system trial, the team is currently in the process of sourcing testing for permeate salinity, chloramine and boron levels, total dissolved solids, and bacteria content.

Owing to the generosity of our sponsors, we will be able to afford all necessary components needed to construct the P.O.C. 2 model and have therefore made the official decision to pursue this with remaining funds. Purchases have been made for the sediment and carbon pretreatment filters and their respective housings. These, coupled with the donated ultraviolet light system, will give the project the capability to operate with seawater.

Update 6: Status Before Campus Closure

Last week, the team mounted a side panel onto our P.O.C. design, officially marking the transition to P.O.C. model 2. This sidewall, which can be seen in our renderings, is for supporting pretreatment filters and the UV disinfection light. Both the carbon and sediment filters, along with the UV lamp module have already been mounted. Unfortunately, it was discovered during recent communication with the pump manufacturer that the current pump should not be operated at 24V and therefore it will be sent back and replaced with the 24V model.

Continuing with electrics, the team recently installed a Victron Battery Monitor module donated by Chris from Tekris Power Electronics. We are extremely grateful for this item as we were not seeking it, rather it was donated to us because Chris thought it would be useful. With it, we are able to see in real-time the current draw through the battery and voltage across its terminals, along with a handful of other useful parameters, all from our smartphones through Bluetooth connectivity. As a first test, we observed the response of the uncoupled DC motor and confirmed the no-load-amperage (NLA) listed on the manufacturer’s certification sheet.

With that being said, unfortunately, all TCNJ students have been sent home per institution’s response to the new novel coronavirus (COVID-19). Since then, the Governor has shut down all universities until further notice, and our campus will be closed indefinitely with in-person lectures will beginning 3/23. While we are saddened by the uncertain fate of our prototype, we fully support the college’s decision in their effort to reduce the spread of illness. We eagerly await the reopening of campus and for this virus to be eradicated to be able to finish this project, hopefully before graduation. We wish good health to all, and will update again should any progress be made, or a definitive end to our project be made.