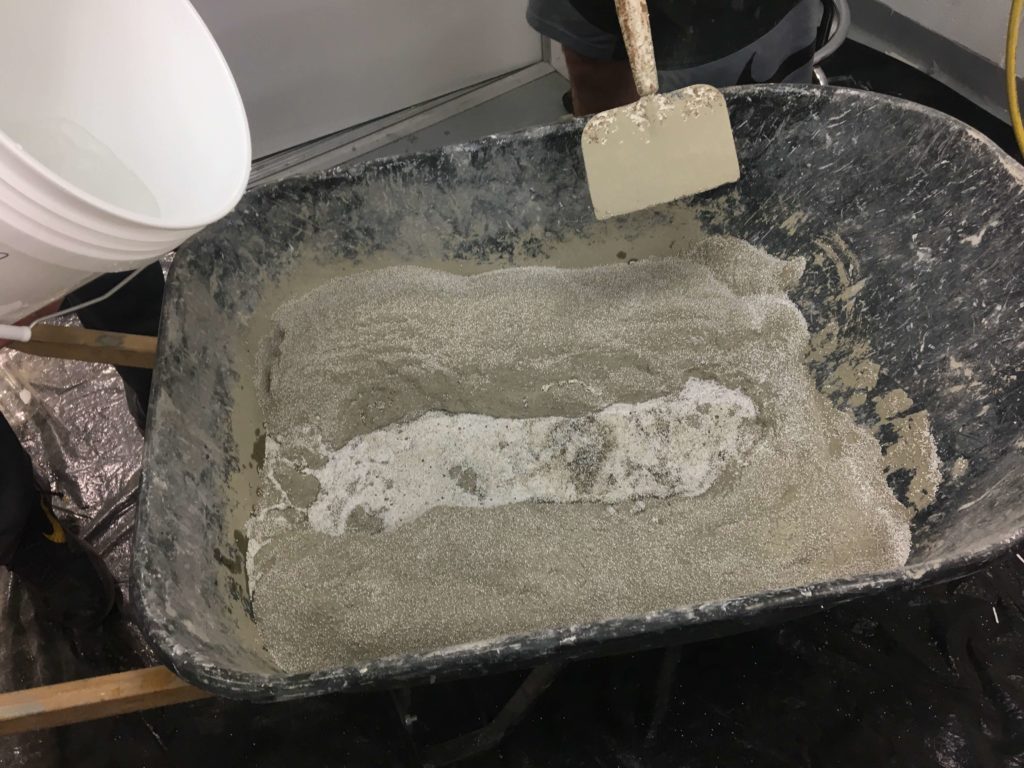

The team began the construction phase this month before Spring Break. The epoxy-coated mold was prepared by covering a layer of carnauba wax to allow for easier removal of the finished canoe. A total of 5 mixes were made using a wheelbarrow, a hoe, and measured out materials in 5-gallon buckets. A trough was made in the middle to where 2/3 of the required water was poured. Once mixed, the rest of the required was poured in to complete the mix. Each batch required about 15 minutes of hand-mixing.

Once the concrete was ready, the team used gloves and trowels to place down the concrete starting from the middle of the canoe towards the ends. The team placed down a 1/4″ thick layer followed by the fiberglass mesh and finally another 1/4″ layer on top. The thickness of the layer was checked using a marked nail with a 1/4″ and 1/2″ lines.

The total process took about 6 hours to complete. The team covered the canoe with wet burlap and a tarp to maintain the moisture throughout its curing process. The team will come back to cut and place the foam ends and cover it with concrete.