On Sunday, April 14, ASCE held its Metropolitan Conference for the Concrete Canoe Competition at Cooks Pond in Denville. Showing up wearing their hula skirts and leis, TCNJ Tiki went into the day with a positive attitude and was looking forward to seeing their hard work put to the test succeed.

The morning began with inspection of both the canoe and the display table. The display table included a poster outline the design components, a copy of the design report, 500 mL samples of all cementitious materials and aggregates used, a 1’ x 1’ sample of reinforcing mesh, and 2 cylinders of the mix design selected. Additionally, a 4’ display section of the canoe demonstrating the application of the concrete and mesh was included.

As the day moved on, the first event was the Swamp Test. The team must submerge the canoe under water, and it must float back up to the surface within 2 minutes, and the canoe was successful!

The next event of the day was the Sprint Race. In both a male and female race, two team members must paddle from the starting line, to a buoy on the other side of the lake and back in the fastest time possible. The male team consisted of Bobby and Jack, who struggled to maneuver the canoe and were forced to jump out and swim to shore. The team realized the boys had taken the canoe out backwards, which made it hard to maneuver. The female team consisted of Taylor and Nicole. After correcting the problem of the backwards canoe, the girls took second overall with a time of 3 minutes and 18 seconds. Lastly, the co-ed race consisted of two laps back and forth across the lake, and had a team of four team members in the canoe, Jeremy, Jack, Nicole, and Taylor. The team worked together and got fourth place, with a time of 6 minutes and 18 seconds.

Overall, it was an exciting and successful day, and the team placed 5th place overall in the competition.

Jeremy has been in the process of performing a structural anlysis of the canoe under the most critical loading condition to find the maximum compressive and tensile stresses. These stresses will help determine the design strength of the final concrete mix that the mix design team should achieve. The critical condition consists of 4 paddler loads conservatively assumed 200 pounds each acting at 20%, 35%, 65%, and 80% of the canoe’s length. The self-weight of the canoe and the bouyancy load is parabolically distributed with based on the changing width and geometry with respect to the length of the canoe. From this loading condition, the shear diagram was developed to determine the moment diagram. The moment diagram was found by integrating all of the shear equations between each of paddler loads. The maximum positive and negative moments will be analyzed and used to find the maximum compressive and tensile stresses.

Jeremy has been in the process of performing a structural anlysis of the canoe under the most critical loading condition to find the maximum compressive and tensile stresses. These stresses will help determine the design strength of the final concrete mix that the mix design team should achieve. The critical condition consists of 4 paddler loads conservatively assumed 200 pounds each acting at 20%, 35%, 65%, and 80% of the canoe’s length. The self-weight of the canoe and the bouyancy load is parabolically distributed with based on the changing width and geometry with respect to the length of the canoe. From this loading condition, the shear diagram was developed to determine the moment diagram. The moment diagram was found by integrating all of the shear equations between each of paddler loads. The maximum positive and negative moments will be analyzed and used to find the maximum compressive and tensile stresses. The Mix Design team has come closer to a final mix over the past month. With their most recent trials, they have achieved multiple mixes that float in water. Mix 8, 9, and 10 have proven to be the most successful in terms of floatability. It is important to note that all of the mixes are in compliance with the 2019 ASCE Rules and Regulations, especially the use of 25% aggregates, discluding microspheres and cenospheres, and mineral fillers.

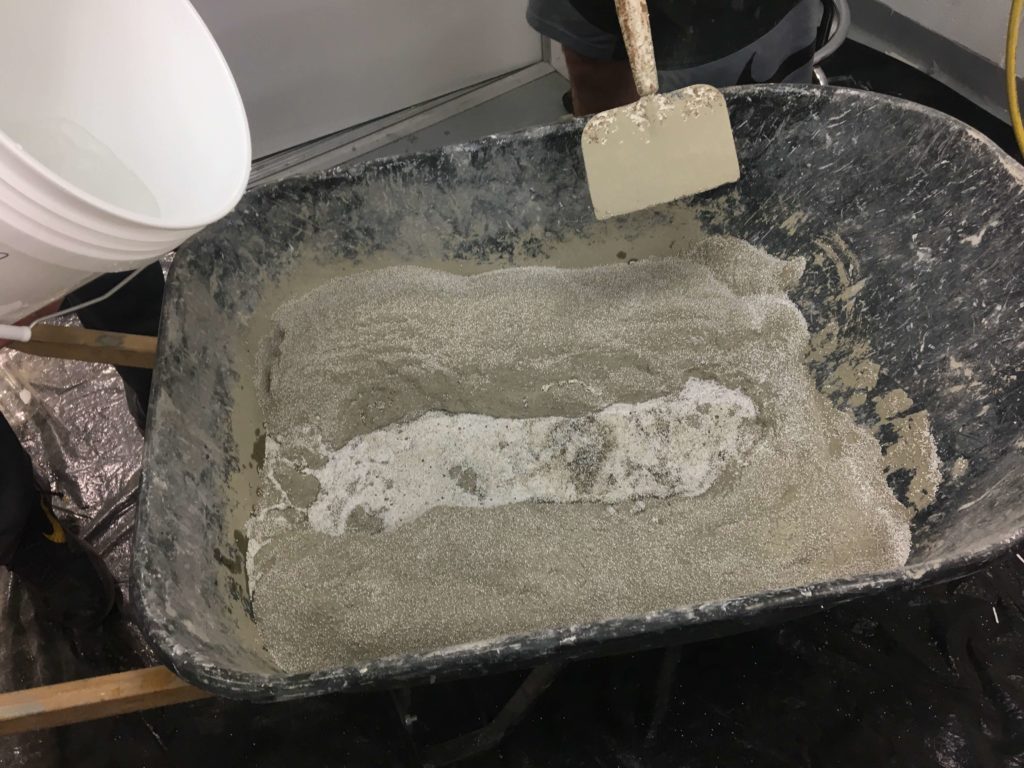

The Mix Design team has come closer to a final mix over the past month. With their most recent trials, they have achieved multiple mixes that float in water. Mix 8, 9, and 10 have proven to be the most successful in terms of floatability. It is important to note that all of the mixes are in compliance with the 2019 ASCE Rules and Regulations, especially the use of 25% aggregates, discluding microspheres and cenospheres, and mineral fillers.  Two weeks after the Mix Team let the cubes cure, the team went in to test their strengths. It was predicted the second mix would have the highest compressive strength, as the first mix’s aggregates were too large for the mold, making it difficult to fill with the other materials and multiple aggregates, and the third mix’s aggregates were run through a #4 sieve and would have less strength.

Two weeks after the Mix Team let the cubes cure, the team went in to test their strengths. It was predicted the second mix would have the highest compressive strength, as the first mix’s aggregates were too large for the mold, making it difficult to fill with the other materials and multiple aggregates, and the third mix’s aggregates were run through a #4 sieve and would have less strength.