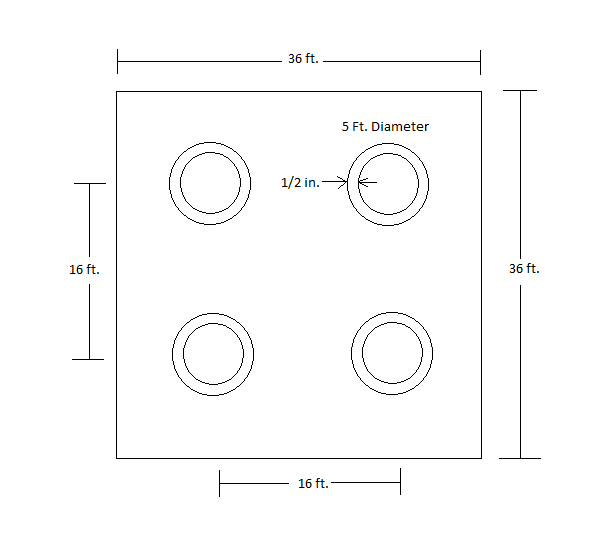

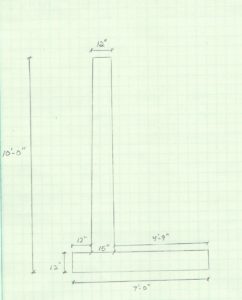

Prestressed concrete piles were originally proposed for the deep foundation design. Once design began it was determined that it would require multiple piles with large diameters in order to reduce the lateral deflection to an acceptable amount. Driving these large piles in such close proximity to the required depths was not feasible, therefore concrete drilled shafts with permanent steel casing were selected for the deep foundation design instead. For the deep foundation design at both the piers and abutments, four 5 feet diameter drilled shafts were selected. While the diameter is 5 feet in total, the drilled shafts have ½” thick steel permanent casing around the concrete. Making the diameter of the concrete 49 inches with a compressive strength of 6000 psi. The total length of the drilled shaft for the piers is 130 feet, with an embedment depth of 110 feet. For the abutments the total length of the drilled shafts are 110 feet embedded fully into the soil without any stick height. The following diagram displays the drilled shaft configuration for both the piers and abutments.